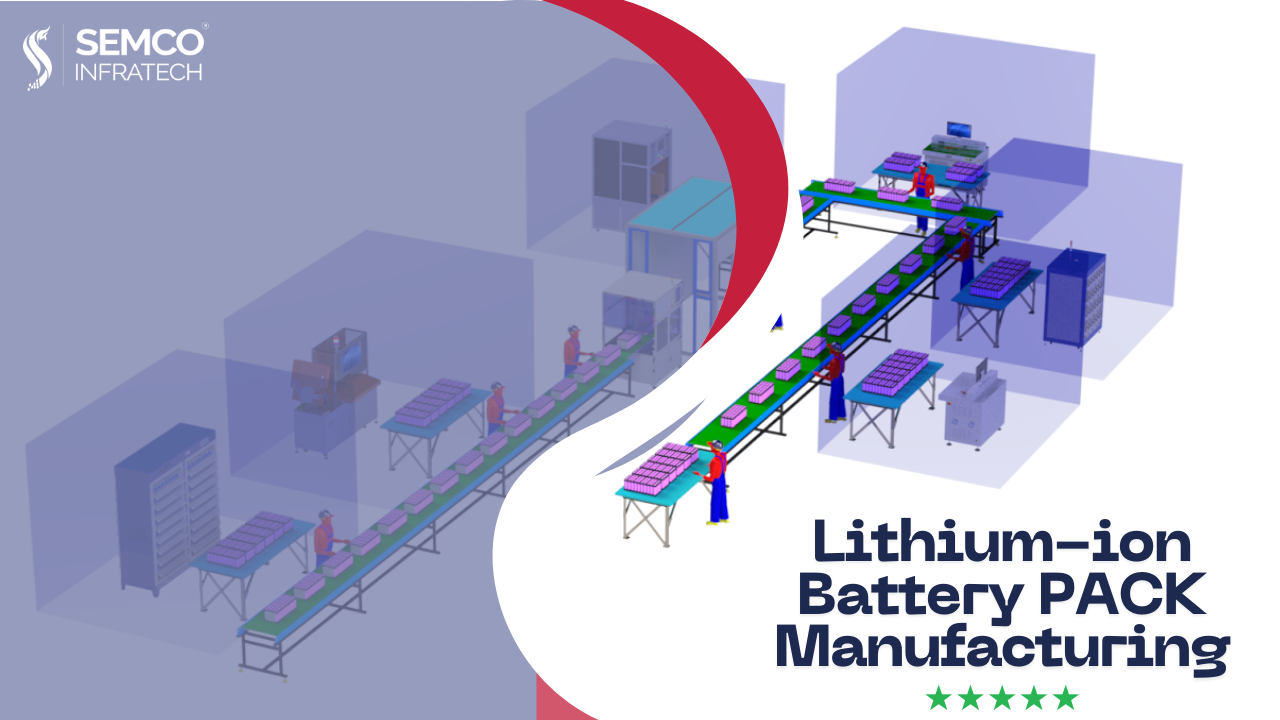

The manufacturing of lithium-ion battery packs is a highly precise and controlled process that plays a pivotal role in delivering reliable and high-performance power solutions.

This final stage in the lithium-ion battery manufacturing process integrates individual cells into fully functional battery modules, complete with safety and management systems.

These battery packs are critical components in electric vehicles (EVs), energy storage systems, and various portable electronic devices.

Key Stages in Lithium-ion Battery Pack Manufacturing

1. Battery Cell Sorting and Grouping

- Selection: Choose cells with matching characteristics such as internal resistance, voltage, and capacity.

- Grouping: Create uniform groups to ensure balanced battery performance and longevity.

- Testing: Perform capacity, voltage drop, and charging/discharging cycle tests to validate cell integrity.

2. Cell Assembly and Spot Welding

- Fixture Placement: Arrange cells precisely in designated fixtures.

- Spot Welding: Use automatic battery welding machines to connect cells and components for optimal conductivity.

- Quality Inspection: Verify weld strength and detect any possible welding faults or irregularities.

3. Battery Module Assembly

- Connect Modules: Combine cells in series or parallel configurations to meet voltage and capacity specifications.

- BMS Integration: Install a suitable Battery Management System (BMS) to monitor parameters like temperature, voltage, and current flow.

4. Battery Pack Testing and Quality Control

- Functional Testing: Validate module efficiency, safety, and performance against industrial benchmarks.

- Leakage Testing: Ensure proper sealing with no fluid or gas leaks.

- Visual Inspection: Identify physical deformities, alignment issues, or structural defects.

Challenges and Key Considerations

- Cell Consistency: Uniform cell performance is vital to prevent imbalance in battery pack operations.

- Welding Quality: Reliable welding avoids short circuits, overheating, and other hazards.

- BMS Integration: Proper BMS selection and integration are essential for battery safety and efficiency.

- Safety Compliance: All processes must comply with global battery safety standards like UN 38.3, UL 2580, and ISO 26262.

Conclusion

The process of lithium-ion battery pack manufacturing involves meticulous steps from cell sorting to final testing and assembly. Each phase plays a critical role in ensuring the performance, safety, and reliability of the battery module. With proper attention to quality and industry standards, manufacturers can deliver durable and efficient battery packs suitable for modern applications like EV batteries, renewable energy systems, and industrial battery solutions.