The rise of electric vehicles, renewable energy systems, and portable electronics has significantly increased the demand for lithium-ion batteries. But behind these powerful energy sources lies a highly intricate and controlled manufacturing process.

From raw materials to finished products, battery-making machines and advanced battery-making equipment are essential in ensuring efficiency, precision, and safety at every stage.

Understanding the Fundamentals

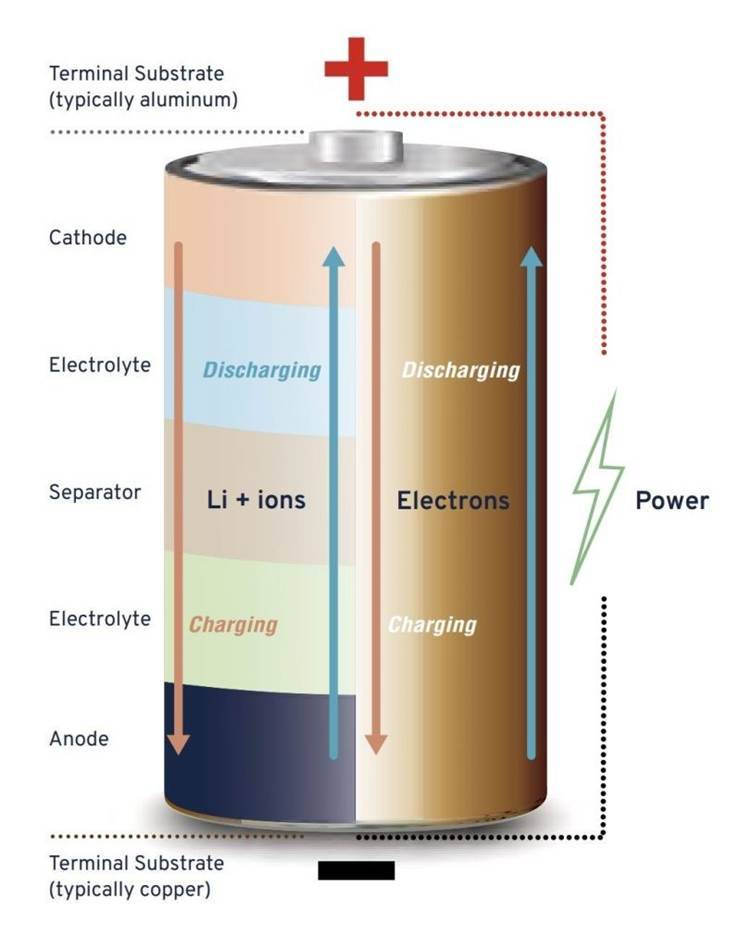

Before diving into the production process, it’s crucial to understand the core components of a lithium-ion battery:

- Positive Electrode: Made from materials such as lithium cobalt oxide (LCO), lithium nickel manganese cobalt oxide (NMC), or lithium iron phosphate (LFP).

- Negative Electrode: Typically composed of graphite.

- Separator: A porous membrane that separates the electrodes while allowing lithium ions to flow.

- Electrolyte: A gel or liquid that enables ion movement between electrodes.

- Current Collectors: Usually, aluminium for the positive electrode and copper for the negative, which provide a conductive path for electrons.

The battery works through the reversible movement of lithium ions between electrodes. During charging, lithium ions migrate to the negative electrode; during discharge, they return to the positive side, producing electrical energy.

The Lithium-Ion Battery Assembly Process: A Multi-Stage Journey

The lithium-ion battery assembly process can be categorized into three key stages:

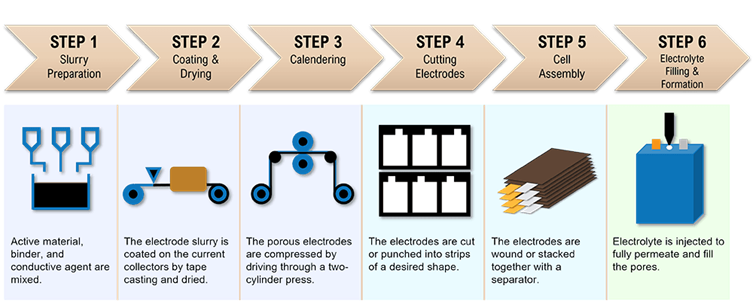

1. Front-End: Electrode Manufacturing

This initial phase focuses on producing high-performance electrodes, a critical step in the battery cell-making machine workflow.

- Slurry Preparation: Active materials (e.g., LCO or graphite) are mixed with binders like PVDF and conductive agents to form a uniform slurry.

- Coating: The slurry is precisely applied to metal foils using high-precision battery-making equipment, ensuring uniform thickness.

- Drying & Calendaring: Coated electrodes are dried to eliminate solvents and then compressed for better conductivity.

- Slitting & Die Cutting: Electrodes are cut into specific dimensions to fit the battery cell, making machine specifications.

2. Middle-End: Cell Assembly

The second stage of the lithium-ion battery assembly process involves assembling the core components.

- Winding/Stacking: Positive and negative electrodes are alternately layered with separators to form a cell stack.

- Electrolyte Filling: The electrolyte is carefully injected into the cells to enable ion movement.

- Sealing: The cells are sealed using heat or ultrasonic sealing to avoid leakage and ensure safety.

3. Back-End: Formation and Packaging

The final stage is about bringing the battery to life.

- Formation: Cells undergo multiple charge-discharge cycles to stabilize their chemistry.

- Testing & Sorting: Advanced battery-making machines test each cell for voltage, capacity, and other parameters. Cells are then sorted accordingly.

- Packaging: Assembled cells move into the lithium battery pack assembly stage, where they are configured into packs, enclosed, and prepared for shipment.

Key Challenges in Lithium Battery Manufacturing

- Quality Control: Every step, from mixing to testing, demands extreme precision.

- Safety: Mishandling materials or processes can result in thermal runaways or fire hazards.

- Environmental Responsibility: Managing chemical waste and emissions is critical for sustainability.

- Technological Advancements: The demand for higher capacity and faster charging batteries drives constant innovation in battery-making equipment.

Conclusion

The lithium-ion battery assembly process is a sophisticated, multi-layered operation that relies heavily on precision, quality, and cutting-edge technology. With growing applications in EVs, consumer electronics, and energy storage, understanding this process—and the role of battery-making machines—is vital. As innovations continue to emerge, the evolution of lithium battery pack assembly will remain central to the future of sustainable energy solutions.