In the world of electric vehicles (EVs), the seamless synergy between battery packs and Battery Management Systems (BMS) plays a crucial role in ensuring optimal performance, longevity, and safety. This article explores the complex relationship between BMS and battery packs, providing insight into their joint efforts to power transportation in the future.

Comprehending Battery Packs: The Engine of Electric Vehicles

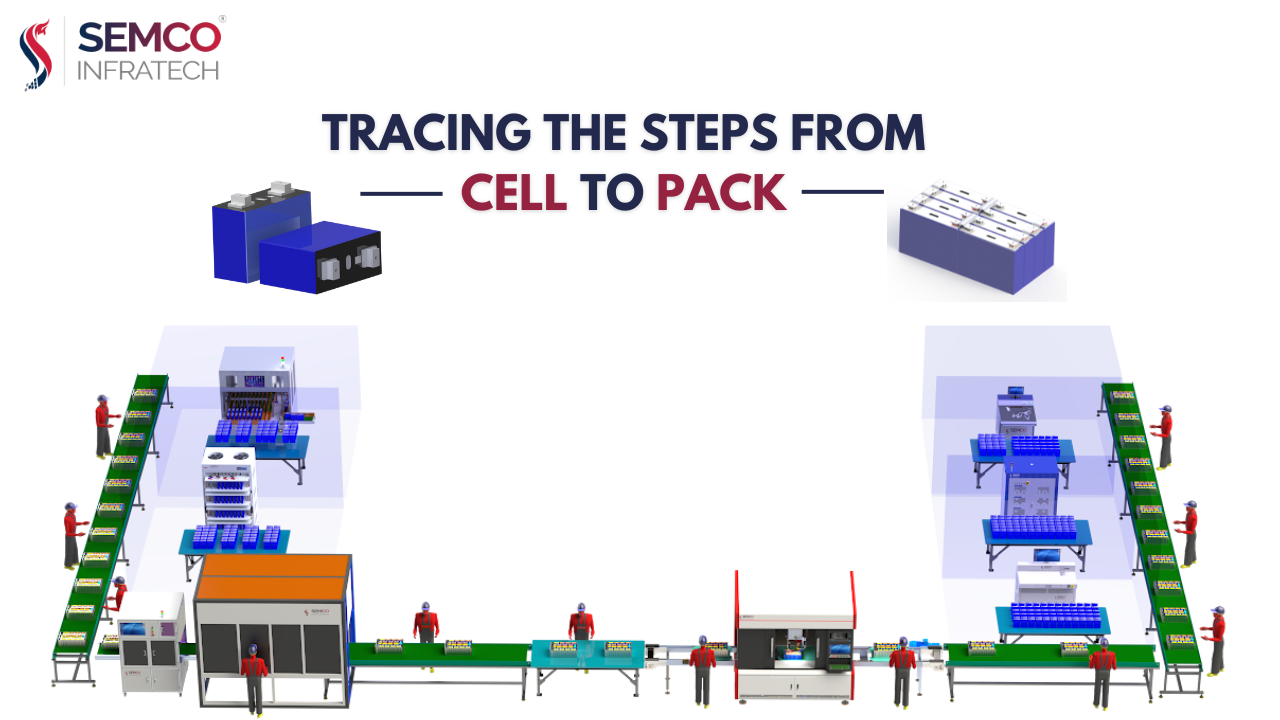

High-capacity battery packs are essential for the effective storage and delivery of energy in electric vehicles. These packs are made up of separate battery cells arranged in modules to provide a strong power source for the car. Although these cells’ chemistry, arrangement, and composition differ amongst EV models, their overall role in the vehicle’s operation is always crucial.

- Battery Management Systems (BMS): The Guardian of Efficiency and Safety Now introduces the Battery Management System, an advanced electronic control system that acts as the battery pack’s protector. To guarantee maximum performance and security, the BMS keeps an eye on, controls, and safeguards each individual cell inside the pack. Its main duties include monitoring temperature, preventing overcharging or over-discharging, and balancing cell voltages.

- The Symbiotic Connection: Communication and Coordination Battery packs and BMS are connected not only physically but also primarily through constant communication. Every single cell in the battery pack has sensors installed in order to provide the BMS with real-time data. The BMS needs this data in order to make informed decisions about battery health in general and charging and discharging in particular.

- Balancing Act: Ensuring Uniform Cell Performance, The BMS is essential in maintaining the balance of voltage between individual cells. Variations in manufacturing quality or temperature swings can cause changes in cell performance over time. By redistributing energy, the BMS actively manages these imbalances and makes sure that every cell operates within a safe and efficient range.

- Temperature Management: Preventing Thermal Runaway Thermal runaway poses a risk to battery packs. The BMS is intended to keep an eye on temperature fluctuations and regulate them by bringing on heating or cooling systems as required. By taking this proactive measure, the risk of overheating is reduced and the EV’s overall safety is improved.

- Optimizing Charge and Discharge Cycles: Prolonging Battery Life In order to maximize charge and discharge cycles and avoid circumstances that can shorten the battery pack’s lifespan, the BMS is essential. The BMS plays a crucial role in prolonging the battery’s lifespan and mitigating the environmental impact of electric vehicles (EVs) by meticulously overseeing these processes.

- Future Prospects: Advancements in Battery-BMS Integration As technology advances, the integration between battery packs and BMS is expected to become even more sophisticated. In the field of electric vehicles, improved communication protocols, predictive maintenance algorithms, and adaptive control strategies are in the works and promise increased effectiveness, dependability, and safety.

In conclusion, the interplay between electric vehicle battery packs and battery management systems is a harmonious technological dance that guarantees our future power source will be safe, sustainable, and efficient. This dynamic pair will surely lead the way for a new era of electric mobility as long as advancements in technology continue.