In the realm of electrochemical energy storage, lithium-ion battery energy storage stands out as a mature and rapidly advancing technology. Within this domain, lithium-ion battery PACK technology emerges as a crucial element. But what exactly is a battery PACK, and how does its complete production line unfold?

Let’s delve into these concepts.

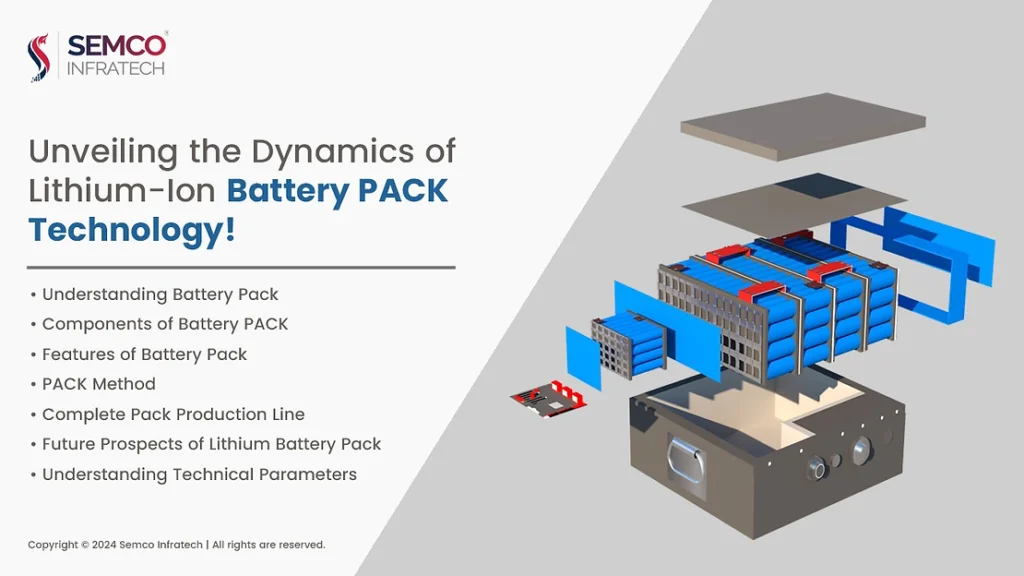

1. Understanding Battery Pack

The lithium-ion battery PACK, also known as a battery module, is an integral part of the lithium-ion battery production process. It involves the connection of multiple lithium-ion monomer cell groups in series, taking into account factors such as mechanical strength, thermal management, and Battery Management System (BMS) integration.

Key technologies associated with battery PACKs include overall structural design, welding and processing process control, protection levels, and active thermal management systems. When two or more batteries are connected in series or parallel to meet specific customer requirements, it is referred to as a PACK.

2. Components of Battery PACK

The essential components of a battery PACK consist of a single battery module, electrical system, thermal management system, box, and BMS.

- Battery Module: This serves as the “heart” responsible for storing and releasing electrical energy.

- Electrical System: Comprising copper liners, high-voltage wire harnesses, low-voltage wire harnesses, and electrical assurance devices, it acts as the circulatory and neural network of the battery PACK.

- Thermal Management System: Utilizing methods such as air cooling and liquid cooling, this system ensures the battery operates at an optimal temperature, enhancing its cycle life.

- Box: Comprising a box, box cover, metal bracket, panel, and fixing screws, it functions as the “bone” providing support, mechanical resistance, and environmental protection.

- BMS (Battery Management System): Serving as the “brain,” BMS is responsible for measuring parameters such as voltage, current, and temperature, as well as performing functions like equalization.

3. Features of Battery Pack

Key features of a lithium battery PACK include a high degree of consistency, lower cycle life compared to single batteries, specific usage conditions, protection requirements for voltage and capacity, and adherence to design specifications.

4. PACK Method

The battery module is formed through string composition, either in series or parallel, affecting voltage and capacity. The cell requirements involve selecting compatible cells, and the PACK process can be realized through welding methods like laser welding or through contact with elastic metal sheets.

5. Complete Pack Production Line

A lithium battery pack production line encompasses six core links: cell manufacturing, cell testing, cell grading, cell assembly, packaging, and quality inspection. Cell manufacturing and cell assembly are crucial in determining the overall performance and quality of the lithium battery pack.

6. Future Prospects of Lithium Battery Pack

The future of lithium battery pack production includes a focus on intelligence, greening, personalization, and safety. Incorporating technologies like artificial intelligence and the Internet of Things aims to enhance automation, efficiency, and environmental sustainability.

7. Understanding Technical Parameters

Technical parameters such as combination method, rated capacity, and rated energy play a vital role in defining the characteristics of a battery PACK.

Combination method: 1P24S

S stands for series cell, P stands for parallel cell, and 1P24S means: 24 strings.

▷ Rated capacity

The rated capacity of the battery refers to the capacity of the battery that can work continuously for a long time under rated operating conditions. The rated capacity of the battery is C, unit amp; it is the product of the discharge current (A) and the discharge time (h).

▷ Rated energy

Rated energy (Wh) = nominal capacity (Ah) * nominal voltage (V), which also means that the total energy released by a battery is related to capacity and voltage.

Conclusion

As the demand for energy storage solutions grows, the lithium-ion battery PACK production line is evolving to meet higher standards of performance and quality. Future advancements in automation, environmental sustainability, customization, and safety are expected to shape the landscape of lithium battery pack production.