Integrating a high-voltage battery pack into an electric vehicle (EV) is no small feat. The complexity arises from the pack’s substantial size, considerable weight, and the critical safety measures required during its operation. With the growing demand for lithium-ion batteries and advancements in battery-making machines, manufacturers must take a holistic approach to integration that balances safety, performance, and efficiency.

Key Factors in Battery Pack Layout

1. Maximizing Space Utilization

Efficiency is at the heart of every EV design. The goal is to fit the largest feasible lithium-ion battery pack within the available chassis space. A larger battery not only extends driving range but also reduces charging intervals, greatly improving the user experience.

- Space Optimization: Engineers leverage innovative packaging techniques, like underfloor battery placement, to maximize interior space. These methods are tightly aligned with modern lithium battery pack assembly strategies to avoid compromising passenger or cargo capacity.

2. Ensuring Safety in Extreme Conditions

Safety is non-negotiable in EV design, particularly with high-voltage lithium-ion battery assembly.

- Collision Resistance: Battery packs must be shielded with robust enclosures and mounted in impact-protected zones to prevent rupture or thermal events during collisions.

- Rollover and Impact Protection: Thoughtful mounting systems help the battery withstand rollovers and high-impact events, reducing the risk of damage.

- Intrusion Prevention: Engineering safeguards ensure the battery stays isolated from the passenger cabin during severe impacts, preserving occupant safety.

3. Minimizing Impact on Vehicle Dynamics

The integration of lithium-ion battery packs can heavily influence a vehicle’s handling and comfort.

- Weight Distribution: The battery’s mass affects the vehicle’s centre of gravity. Strategic placement is essential to maintain balance, handling, and driving comfort.

- Structural Integrity: Improper placement can strain the chassis and suspension. Using advanced battery-making equipment helps reinforce these systems to endure the battery’s weight without degrading over time.

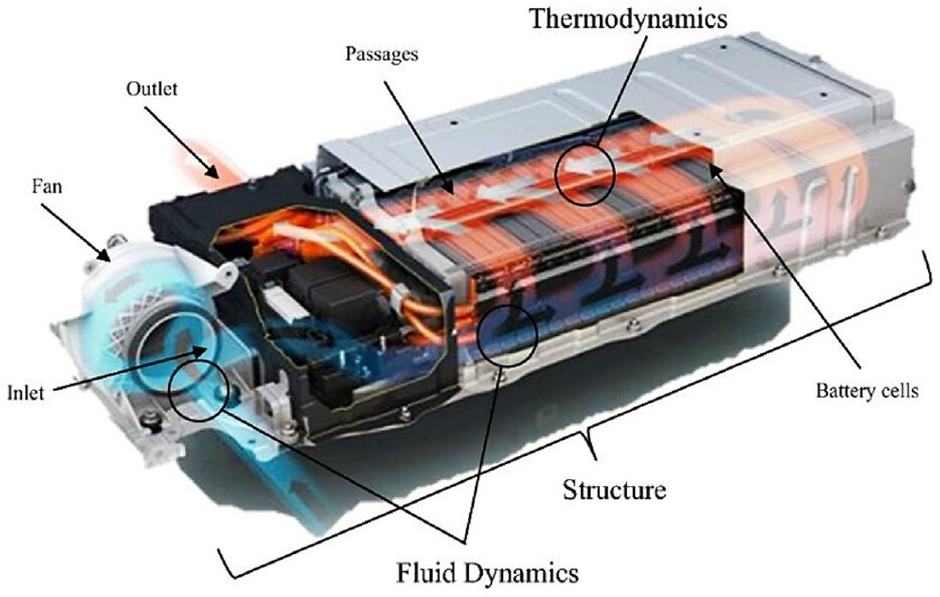

4. Thermal Management

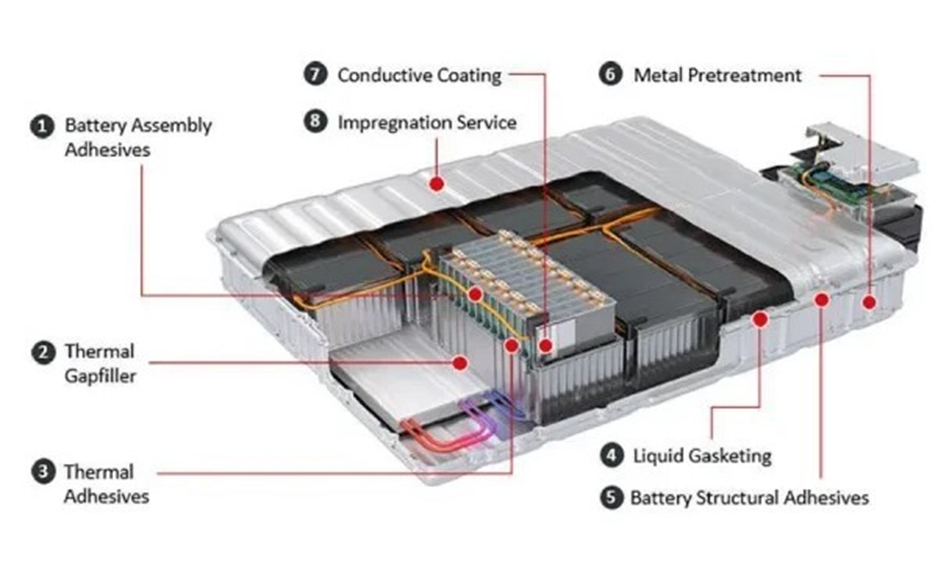

Lithium-ion batteries produce significant heat during operation. Effective thermal regulation is critical for performance and longevity.

- Heat Dissipation: Managing heat during charge/discharge cycles is essential to prevent performance degradation and risks like thermal runaway.

- Cooling/Heating Systems: Integrated systems, often part of the lithium-ion battery assembly process, help maintain safe temperatures under varied environmental and operating conditions.

5. Optimizing Vehicle Architecture

The integration of a battery pack goes beyond just placement—it influences the entire design framework of the EV.

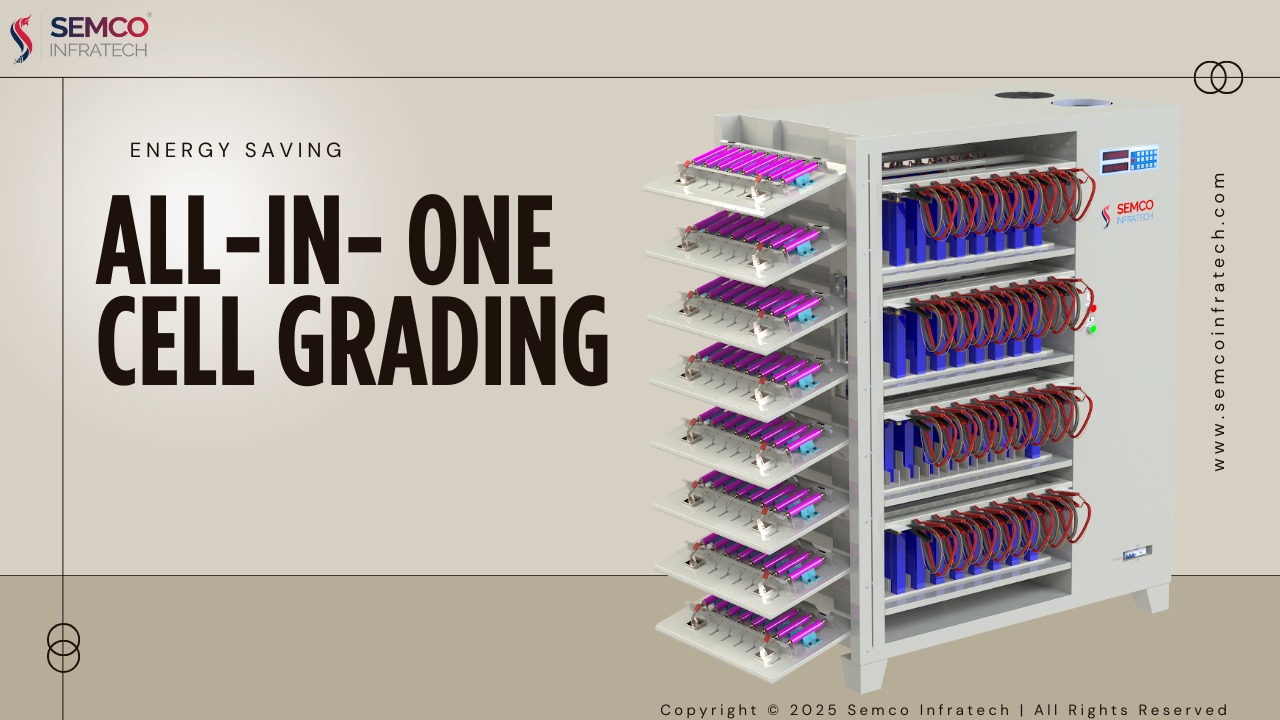

- Space Constraints: Large battery cell making machines are engineered to Mold cells that fit unique architectural demands without sacrificing design or utility.

- Centre of Gravity: Lowering the pack’s position contributes to stability and improves ride quality, a key consideration in modern EV development.

Conclusion

Successfully integrating a lithium-ion battery pack into an electric vehicle requires an intricate balance of design, performance, and safety. By focusing on space optimization, extreme condition safety, vehicle dynamics, thermal management, and holistic architecture, manufacturers can create EVs that are not only safer and more efficient but also more appealing to consumers.

Advancements in battery-making machines, battery-making equipment, and the lithium-ion battery assembly process continue to revolutionize the way EVs are built. From initial battery cell making machines to complete lithium battery pack assembly, each component plays a pivotal role in shaping the electric future.