Introduction: Why Supplier Selection Is a Strategic Decision

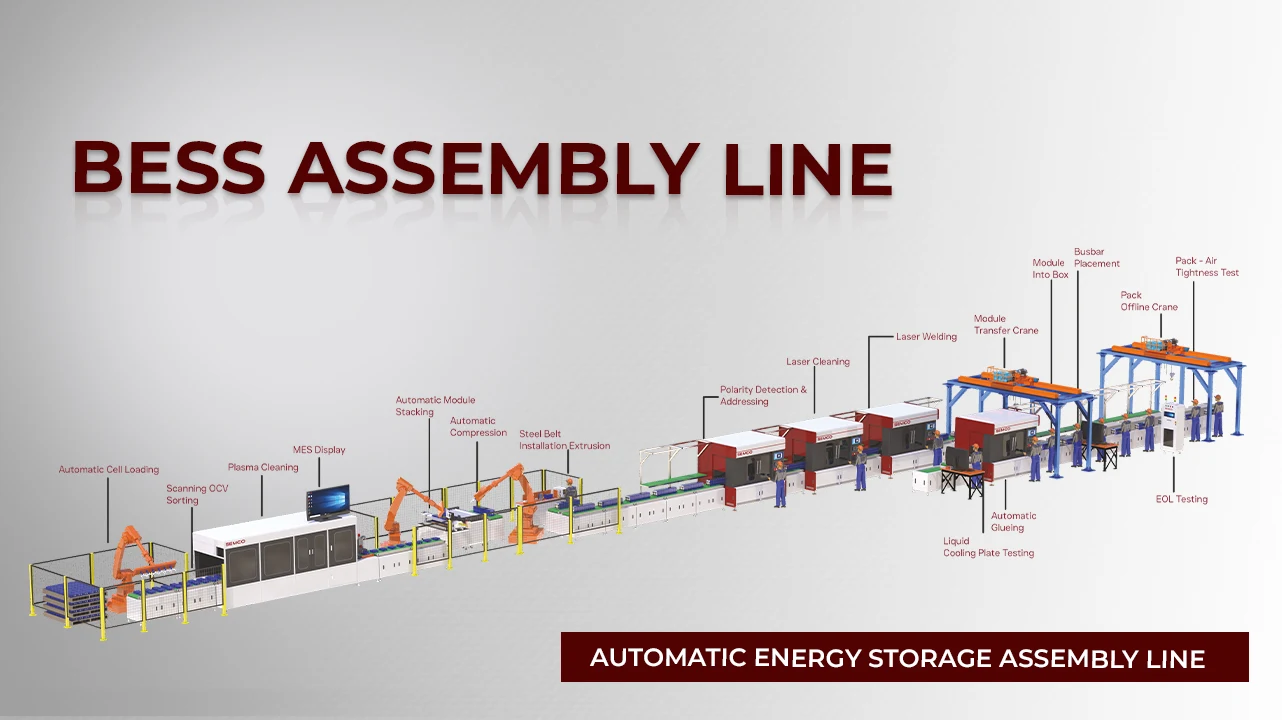

Manufacturers scaling cylindrical lithium-ion cell production face a hard reality: manual or semi-automated lines cannot meet today’s cost, quality, or throughput targets. Yield loss, inconsistent weld quality, and safety exposure compound rapidly once volumes cross the tens of millions of cells per year. This is why decision-makers actively search for which companies offer fully automated cylindrical battery assembly lines that are proven, scalable, and production-ready.

The challenge is not automation itself—it is integration. A viable solution must synchronize electrode handling, cell assembly, laser welding, electrolyte filling, formation, and inline inspection without creating new bottlenecks. Vendors vary widely in depth of process ownership, software maturity, and long-term service capability. Choosing the wrong partner locks manufacturers into fragile lines that underperform at scale. This article examines the leading companies in this space, what they actually deliver, and how to evaluate them based on real production constraints rather than marketing claims.

Leading Asian OEMs Dominating High-Volume Cylindrical Cell Lines

Asian equipment manufacturers—particularly from Japan, South Korea, and China—dominate fully automated cylindrical battery assembly lines at GWh scale. This is not accidental. These vendors evolved alongside tier-one cell manufacturers and have deep process know-how rather than just mechanical automation expertise.

Key players include companies such as Wuxi Lead, Yinghe Technology, and Hitachi High-Tech. Their strength lies in vertically integrated equipment portfolios covering cell winding, can insertion, laser welding, electrolyte filling, and formation aging systems. These suppliers focus heavily on takt-time stability and yield protection, not just headline throughput.

Common characteristics of top Asian OEMs include:

- Proven installations running 24/7 at high OEE

- Mature inline metrology for weld integrity and leak detection

- Strong MES integration for traceability at cell level

The trade-off is limited customization flexibility and longer lead times. These suppliers excel when manufacturers prioritize volume, repeatability, and predictable ramp-up over experimental cell designs.

European Automation Specialists Focused on Precision and Compliance

European companies approach cylindrical battery production differently. Firms such as Manz, Dürr, and teamtechnik emphasize precision automation, modular line architecture, and regulatory compliance. Their systems are typically selected by manufacturers targeting premium applications or operating in heavily regulated environments.

European fully automated cylindrical battery assembly lines often prioritize:

- High-precision handling for tight mechanical tolerances

- Advanced safety zoning and functional safety standards

- Flexible platforms adaptable to multiple cell formats

These systems are rarely the fastest on paper, but they are engineered for consistency and long-term maintainability. Software layers, digital twins, and predictive maintenance are usually stronger than those offered by low-cost competitors.

However, cost is a real constraint. Capital expenditure is significantly higher, and integration timelines can stretch if upstream or downstream processes are not equally mature. These suppliers make sense when compliance, traceability, and process transparency matter more than absolute cost per cell.

Turnkey Line Integrators vs Process-Focused Equipment Vendors

Not all companies offering fully automated cylindrical battery assembly lines build every machine themselves. Some act as system integrators, combining best-in-class equipment from multiple OEMs into a single automated line. This model can be effective—but only if governance is strong.

Turnkey integrators typically add value through:

- Unified controls architecture and MES integration

- Line-level balancing and bottleneck elimination

- Single-point responsibility during commissioning

The risk is process ownership dilution. When weld quality issues or formation inconsistencies arise, accountability can become fragmented across multiple sub-suppliers. Manufacturers must assess whether the integrator truly understands electrochemical process constraints or is simply coordinating hardware.

In contrast, process-focused vendors control fewer steps but deliver deeper optimization within their scope. The right choice depends on whether internal teams can manage multi-vendor coordination without slowing ramp-up.

How to Evaluate Automation Vendors Beyond Brochures

Marketing materials rarely reveal whether a fully automated cylindrical battery assembly line will survive real production stress. Decision-makers should focus on evidence, not promises.

Critical evaluation criteria include:

- Reference lines operating at comparable scale and chemistry

- Demonstrated yield stability beyond pilot volumes

- Depth of after-sales support and spare parts localization

- Software maturity, not just mechanical automation

Ask direct questions about scrap rates during ramp-up, downtime recovery strategies, and how process drift is detected and corrected. Vendors that avoid specifics usually lack operational depth.

Also evaluate whether the supplier can scale with future format changes. Rigid automation optimized for one cell size can become obsolete faster than expected in a rapidly evolving market.

Conclusion: Automation Is Only as Strong as Its Process Ownership

There is no single “best” answer to which companies offer fully automated cylindrical battery assembly lines. Asian OEMs lead in volume and cost efficiency, European suppliers excel in precision and compliance, and integrators bridge gaps when internal expertise is limited.

The real differentiator is not nationality or brand recognition—it is process ownership. Vendors that understand electrochemistry, quality risk, and production economics deliver lines that scale predictably. Those that only automate mechanics create expensive bottlenecks.

For manufacturers, the decision should be ruthless and evidence-based. Demand operating proof, challenge assumptions, and prioritize long-term stability over short-term speed. In high-volume cylindrical cell production, weak automation choices are not fixable later—they are locked into the factory floor.