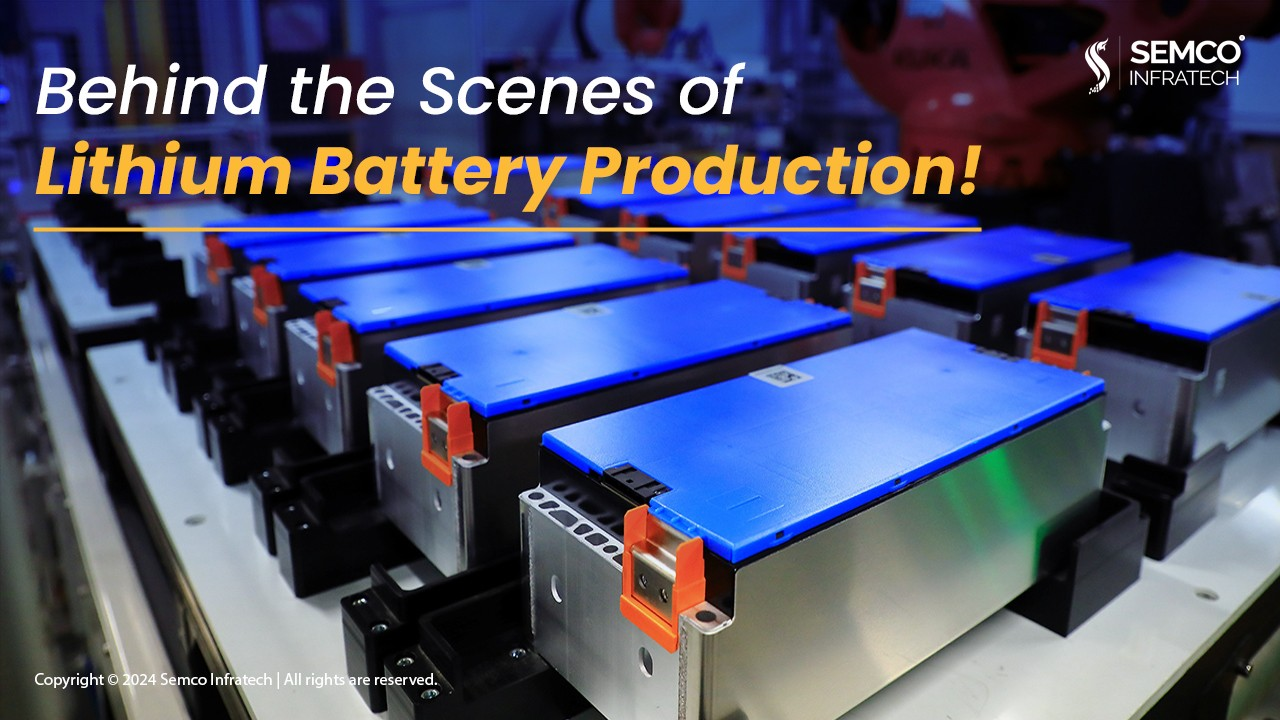

Lithium battery packs are the heart of the new energy revolution, and their assembly is a critical process. This article dives into the key stations and equipment that make up a lithium battery pack production line.

1. Material Preparation Station: The Building Blocks

This station handles the receiving, storage, and precise measurement of raw materials. Here, you’ll find equipment like storage devices for raw materials and weighing equipment to ensure accurate proportions.

2. Cell Assembly Station: Where the Magic Happens

This station is where the positive and negative electrodes, along with a separator, are laminated together to form individual battery cells. The key equipment here includes sheet lamination machines and cell strapping machines.

3. Cell Test Station: Quality Check for Cells

After assembly, cells undergo rigorous testing to ensure their electrical performance meets standards. This station utilizes cell test instruments to measure voltage, capacity, and internal resistance.

4. Cell Matching Station: Finding the Perfect Match

Cells are classified and grouped based on their performance data obtained from testing. This ensures consistent performance within a battery pack. Matching robots and cell classification equipment play a crucial role here.

5. Module Assembly Station: Building the Battery Brain

Individual cells are integrated with other components like the Battery Management System (BMS), which acts as the brain of the battery pack. The BMS typically consists of a computer control system, circuit board, and sensors. This station utilizes module assembly equipment and laser welding equipment for precise assembly.

6. Module Test Station: Double-Checking Performance

Once assembled, modules undergo another round of testing to verify their battery performance and overall functionality. Module test instruments and functional test equipment are the workhorses of this station.

7. Pack Assembly Station: Putting it All Together

The assembled modules are packaged and secured within a protective shell. Pack assembly equipment and sealing equipment are the main players here.

8. Pack Test Station: The Final Hurdle

The final test ensures the overall electrical performance and safety of the assembled battery pack. Pack test equipment and safety test equipment are the last line of defense before the packs are shipped out.

The Key to Success: A Symphony of Stations and Equipment

A well-designed production line with the right equipment at each station is paramount. This meticulous process ensures the performance, quality, and safety of the final product – the lithium battery pack that powers our new energy future. By combining these factors, manufacturers achieve efficient and reliable production of these essential components.

For More Updates Follow Us

WhatsApp – Facebook – Instagram – Twitter – LinkedIn – YouTube