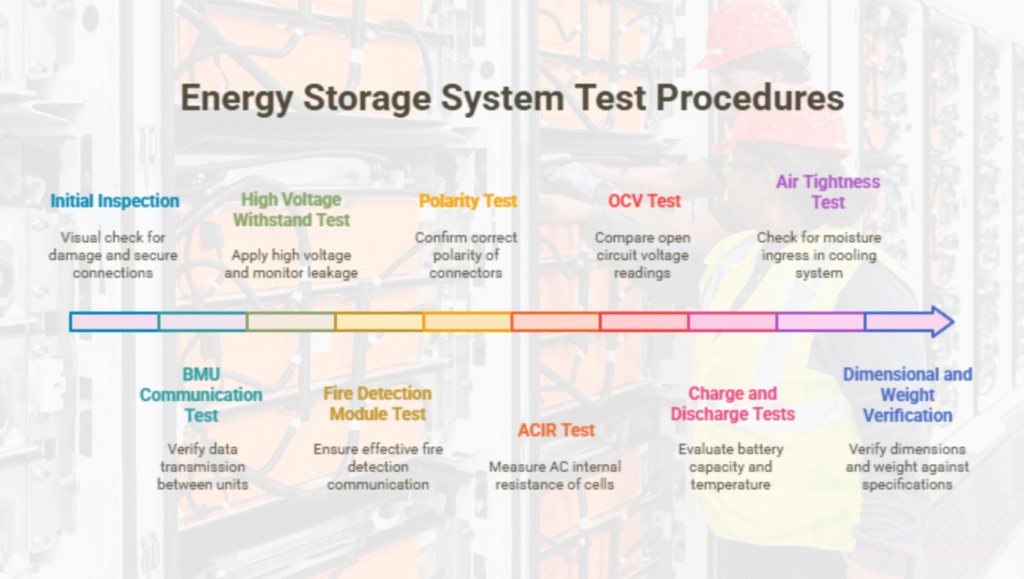

Initial Inspection of Battery Energy Storage Systems

- Visual Inspection:

- Examine the battery system for any signs of physical damage such as dents, cracks, or deformation. Remove any foreign objects that could interfere with operation or pose a safety risk.

- Inspect all electrical connections for tightness and security. Loose connections can lead to increased resistance, overheating, or even electrical failure.

- Ensure that bolts are torqued to the correct specification and that cables and harnesses are routed and secured as per the installation manual.

- Check that all labels and markings are present, legible, and correctly positioned. This is crucial for safety, maintenance, and regulatory compliance.

Functional Tests

- BMU Communication:

- Verify that the Battery Management System (BMS) master unit can communicate with all slave or managed units. Data such as voltage, temperature, and other critical parameters should be accurately transmitted and displayed.

- Test the insulation resistance between the positive and negative terminals and the ground to ensure there are no unintended current paths that could lead to short circuits or safety hazards.

2. High Voltage Withstand Test: Apply a high voltage (higher than normal operating voltage) between the battery terminals and the ground for a specified duration. Monitor for current leakage; excessive leakage indicates insulation failure. This test ensures the system can safely handle voltage surges.

3. Fire Detection Module Communication: Test that the fire detection module communicates effectively with the BMS. Ensure that fire or smoke events are promptly reported, triggering appropriate alarms and safety protocols.

4. Polarity Test: Verify that the polarity of all high-voltage connectors is correct. Incorrect polarity can damage equipment or cause dangerous malfunctions. Use a multimeter or polarity tester to confirm.

5. AC Internal Resistance (ACIR) Test: Measure the AC internal resistance of the battery cells. Elevated resistance may indicate cell degradation or internal faults, which can impact performance and safety.

6. Open Circuit Voltage (OCV) Test: Compare the open circuit voltage measured by the BMS with that measured by a calibrated multimeter. Consistent readings ensure that the BMS is providing accurate data for monitoring and control.

7. Charge and Discharge Performance Tests:

- DCR Test: Measure the DC internal resistance to assess the internal impedance of the battery, which is a key indicator of battery health.

- Capacity Test: Perform charge and discharge cycles to evaluate the battery’s actual capacity and efficiency compared to its rated specifications.

- Temperature Monitoring: Continuously monitor the temperature of battery cells during charge and discharge. Overheating can lead to reduced lifespan or safety incidents, so effective temperature management is essential.

Safety Tests

- Air Tightness Test: Test the air tightness to ensure no moisture can enter the water-cooling system or battery enclosure. Moisture ingress can cause corrosion, short circuits, or other safety issues.

- Dimensional and Weight Verification: Measure the dimensions and weight of the battery pack and compare them against the design specifications. Deviations may indicate installation errors or potential safety concerns.

By conducting these comprehensive tests, it is possible to ensure the safe and reliable operation of energy storage systems.