In today’s rapidly electrifying world, lithium-ion batteries power everything from smartphones and electric vehicles to grid-scale energy storage systems. As the demand for high-performance lithium-ion battery packs continues to grow, ensuring their reliability, performance, and safety becomes essential.

While advancements in battery-making machines and battery-making equipment have significantly improved manufacturing processes, the cornerstone of durable and trustworthy battery products lies in comprehensive Battery Aging Tests.

These tests are more than a quality assurance formality—they are an integral part of Battery Product Development, helping manufacturers fine-tune design, identify risks, and ensure long-term reliability.

The Role of Battery Aging Tests in Lithium Battery Manufacturing

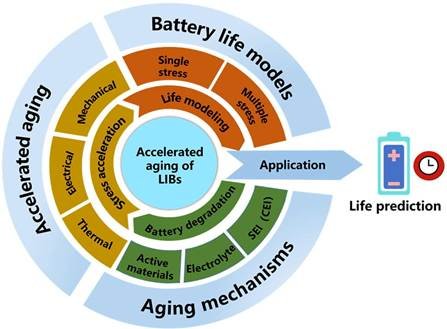

Battery Aging Tests involve subjecting battery cells, modules, or complete packs to accelerated stress conditions to simulate long-term usage. This process reveals the real-world degradation behaviour of lithium-ion batteries, enabling engineers to improve battery cell making machines, refine processes, and enhance material selection throughout the lithium-ion battery assembly process.

Uncovering Hidden Degradation Mechanisms

Aging tests help reveal the most critical deterioration issues affecting lithium battery pack assembly:

- Capacity Fade: One of the primary concerns in Battery Life Cycle Testing is the gradual loss of energy storage capacity. These tests help measure capacity fade under varying conditions to optimize battery chemistry and assembly methods.

- Increased Internal Resistance: Over time, resistance builds within cells, reducing power output and efficiency. Battery Performance Testing quantifies this change to improve thermal management and cell design.

- Loss of Cycle Life: Testing evaluates how many charge-discharge cycles a battery can endure, ensuring the lithium-ion battery packs meet their intended life span.

- Safety Hazards: Aging can result in short circuits, thermal runaway, and gas leakage. Battery Reliability Testing helps manufacturers detect and prevent such hazards during the lithium-ion battery assembly phase.

Boosting Battery Performance and Longevity

Through Battery Aging Tests, manufacturers gain data to enhance several key areas of Battery Product Development:

- Material Optimization: Tests help choose optimal electrode materials and electrolytes that contribute to longer battery life.

- Refinement in Manufacturing: Insights gained can improve battery cell-making machine processes by identifying and eliminating defects.

- Thermal Management: Evaluating heat management systems under aging conditions ensures the safety and stable operation of lithium-ion battery assembly.

- Battery Management System (BMS) Optimization: Data from aging tests supports smarter BMS algorithm development, a critical component in modern battery testing equipment and control systems.

Reducing Failures and Enhancing Customer Satisfaction

Proactive Battery Reliability Testing directly impacts brand perception and customer experience by:

- Minimizing warranty claims and returns

- Boosting product trust and reputation

- Reducing maintenance and service costs

- Increasing customer loyalty

Faster Product Development Cycles

By simulating years of use in a short timeframe, Battery Life Cycle Testing helps engineers make quicker decisions on chemistry, design, and performance metrics. This leads to faster innovation and reduced time-to-market for next-gen lithium-ion battery packs.

Competitive Advantage and Cost Efficiency

Companies that invest in robust Battery Aging Tests can:

- Launch more reliable products

- Avoid costly recalls and service issues

- Differentiate themselves with premium battery-making equipment and processes

- Gain a stronger foothold in competitive markets

Key Types of Aging Tests in the Battery Industry

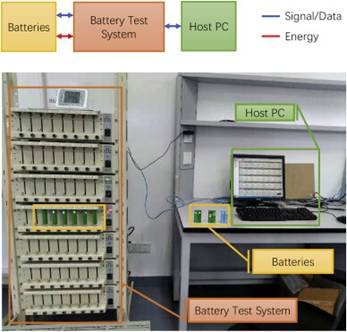

To simulate diverse real-world conditions, multiple testing methods are used in advanced battery testing equipment:

- Calendar Aging: Long-term storage simulation at different temperatures

- Cycle Aging: Performance evaluation over repeated charge-discharge cycles

- Temperature Cycling: Resistance to extreme thermal changes

- Abuse Tests: Overcharge, short circuit, and mechanical shock scenarios

Conclusion

In the competitive world of lithium-ion battery assembly, Battery Aging Tests are not optional—they are essential. They guide innovation, prevent failure, and ensure the safety and longevity of products developed using modern battery-making machines and battery cell-making machines. By investing in high-quality battery testing equipment and integrating these tests into the lithium battery pack assembly workflow, manufacturers can deliver safer, longer-lasting, and more reliable battery solutions to meet the demands of tomorrow.