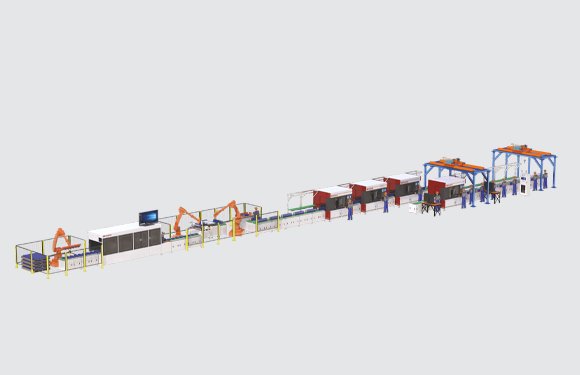

BESS Automated Assembly Line

Leader In Lithium-ion Battery Testing & Assembly Line Solutions

Our Impact at a Glance

Business Areas

Semco provides precision-engineered solutions for lithium-ion battery assembly, testing, and automation, supporting scalable and reliable production for EV, energy storage, and industrial applications.

-

Automated Assembly

-

Testing & Validation

-

Cell Sorting

-

Precision Welding

-

ESS Solutions

-

Plant Setup

Automated Battery Assembly Lines

Turnkey assembly line systems for prismatic, cylindrical, and pouch battery packs — engineered for high-throughput, precision and consistency in manufacturing operations.

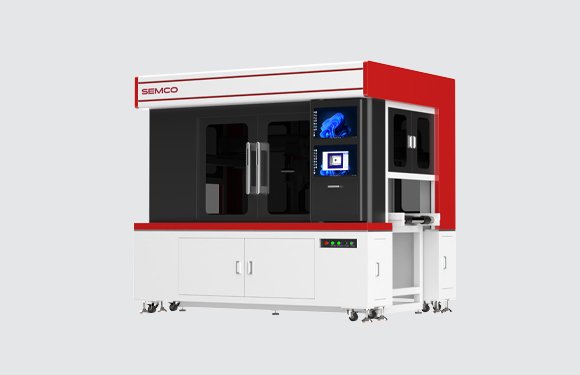

Battery Testing & Validation Equipment

Comprehensive testing solutions including aging cabinets, BMS testers, and OCV/IR test systems to ensure safety, performance and compliance before deployment.

Cell Sorting & Grading Systems

High-accuracy battery cell sorting and grading machines that classify cells by voltage, capacity and internal resistance for uniform pack performance.

Precision Welding & Joining Technology

Advanced spot and laser welding solutions designed for reliable electrical connections in battery modules and pack assemblies.

Energy Storage System (ESS) Solutions

Tailored systems and equipment for utility-scale and industrial energy storage applications, supporting renewable integration and grid stability.

Plant Setup, Integration & Support Services

End-to-end services including facility planning, installation, commissioning, maintenance and ongoing performance optimization.

Our Approach

Engineering Efficiency at Every Stage

Precision Engineering for Smarter Battery Manufacturing

Initial Inquiry & Engagement

Every project begins with a focused discussion. We understand your goals, challenges, and expectations. Key requirements are identified at an early stage. This creates a strong foundation for long-term collaboration.

Our Clientele

Why Choose Us – Semco

Your Trusted Partner in Battery Manufacturing Solutions Where Innovation Meets Reliability in Every Battery Project

End-to-End Expertise

We deliver complete battery manufacturing solutions, managing every stage from system design and engineering to installation and commissioning.

Global-Standard Components

Our systems are built using internationally certified components, ensuring consistent quality, safety, and long-term operational reliability.

Made in India, World-Class Quality

Proudly engineered and manufactured in India, our solutions meet global performance standards and are trusted by customers worldwide.

Proven Track Record

With hundreds of successful installations across diverse industries, we bring proven experience and dependable execution to every project.

Customer-Centric Approach

Every solution is tailored to your specific production needs, ensuring optimal performance, efficiency, and measurable business value.

Future-Ready Solutions

We integrate automation and Industry 4.0 technologies to deliver scalable systems designed for evolving manufacturing demands.

24/7 Service Hotline

Our toll-free support line 0807 1800 782 is available around the clock to provide immediate assistance whenever you need it.

Blog

Faq

Frequently Asked Questions

Quick answers on BESS Assembly Line automation, battery support, safety, customization, and scalability.

What does Semco Infratech do?

What types of equipment does Semco Infratech offer?

The company offers battery testing machines, cell sorting and grading systems, laser welding equipment, and fully automated battery assembly lines.

Which industries does Semco Infratech serve?

Does Semco Infratech provide customized solutions?

Is after-sales support available?

What battery cell types are supported?

Why are battery testing systems important?

Does Semco Infratech work with international clients?

Contact Us

- Patparganj Industrial Area, New Delhi

- sales@semcoindia.com

- +91-9289038327

Send us a message

Review

Trusted by Industry Leaders

Manufacturers and energy solution providers trust our BESS Assembly Line for its reliability, precision, and scalable performance. Here’s what our clients say about working with us.

Semco Infratech has been an invaluable partner in our pursuit of excellence. Their commitment to delivering state-of-the-art precision test and measurement equipment has significantly enhanced our operational efficiency.