In the evolving world of lithium-ion batteries, precision and performance are paramount, especially when it comes to quality control and validation. As electric vehicles, energy storage systems, and portable electronics continue to rely heavily on advanced battery technologies, the need for reliable testing systems becomes increasingly critical.

The HYNN Semco PT 20V 10A 48CH Battery Pack Tester rises to meet this demand with a robust and feature-rich solution tailored for modern battery-making machines and lithium battery pack assembly environments.

An Overview of HYNN Semco PT 20V 10A 48CH Battery Pack Tester

Specially engineered to test compact lithium-ion battery packs up to 20V, the HYNN Battery Pack Tester is ideal for both R&D labs and industrial settings. It caters to a broad spectrum of applications, from battery cell making machine operations for power tools to small-scale solar energy storage systems. With 48 fully independent channels, this system supports high-precision testing and detailed analysis of every single battery under evaluation.

In facilities that manage the lithium-ion battery assembly process, this system proves indispensable. Whether you’re validating performance during production or testing prototype lithium-ion battery assembly, this versatile tool ensures safety, efficiency, and consistency. It’s designed to perform a variety of critical tests including:

- Cycle Life Testing – Analysing longevity through repeated charge-discharge cycles

- Capacity Testing – Measuring energy storage potential for performance optimization

- Charge Retention Testing – Evaluating the battery’s ability to hold a charge over time

- Overcharge & Over-discharge Protection – Ensuring battery durability under extreme conditions

- Internal Resistance Testing – Identifying defects or inefficiencies within battery cells

- Communication with BMS – Seamlessly syncing with Battery Management Systems for real-time data analysis

Such comprehensive testing is crucial for those handling battery making equipment on the production line or those developing custom battery solutions in research labs.

Key Features of the HYNN Semco PT Battery Testing System

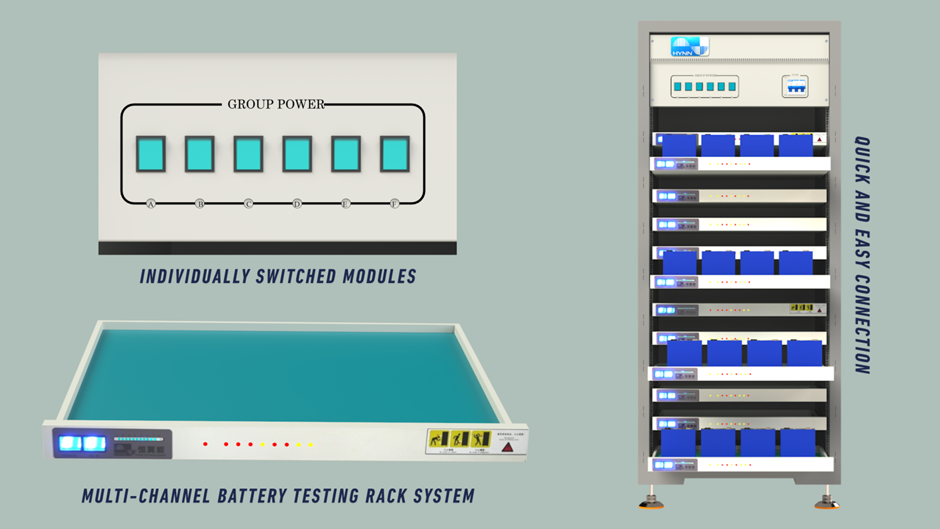

- Independent Channel Operation: Each of the 48 channels allows distinct configurations, ideal for multi-cell batch testing in Hynn Machines-enabled environments.

- Ultra-High Accuracy: With 0.05% precision, it meets the rigorous standards required for high-end lithium-ion batteries.

- CC-CV and CV-CC Control: Seamless power transition modes prevent current overshoot and maintain battery integrity.

- Remote Monitoring: WLAN connectivity allows full control from any networked system, improving oversight in battery labs.

- Four-Wire Output: Ensures accurate voltage readings by compensating for cable losses.

- Modular System Design: Makes maintenance simple and future upgrades easier—perfect for growing battery-making equipment setups.

Advanced Communication and Data Protection

The system incorporates an RJ-45 communication interface for stable and insulated data transfer. This ensures real-time monitoring and protects against power surges or environmental interference—a crucial requirement in modern lithium battery pack assembly operations where accuracy and safety are critical.

Why Choose the HYNN Battery Testing System for Your Lab?

For any lab involved in lithium-ion battery packs or full-scale battery cell making machine production, the HYNN Power Cabinet System and HYNN Battery Cell Tester series provide unmatched versatility and performance. The HYNN Semco PT 20V 10A 48CH is not just a tester—it’s a complete solution for validating battery life cycles, optimizing charge efficiency, and ensuring the integrity of your end product.

Its multi-channel testing capabilities and rich feature set position it as a leading tool in the landscape of Hynn Machines. If you’re engaged in lithium-ion battery assembly or building scalable battery making machine infrastructure, this system is a powerful addition to your equipment lineup.

Conclusion

In today’s competitive battery market, the need for reliable and precise testing systems cannot be overstated. The HYNN Battery Pack Tester is engineered to meet the highest standards of accuracy, flexibility, and data integrity. Whether you’re working on the lithium-ion battery assembly process or scaling your battery-making equipment, this testing system will help you achieve greater quality control and production efficiency.