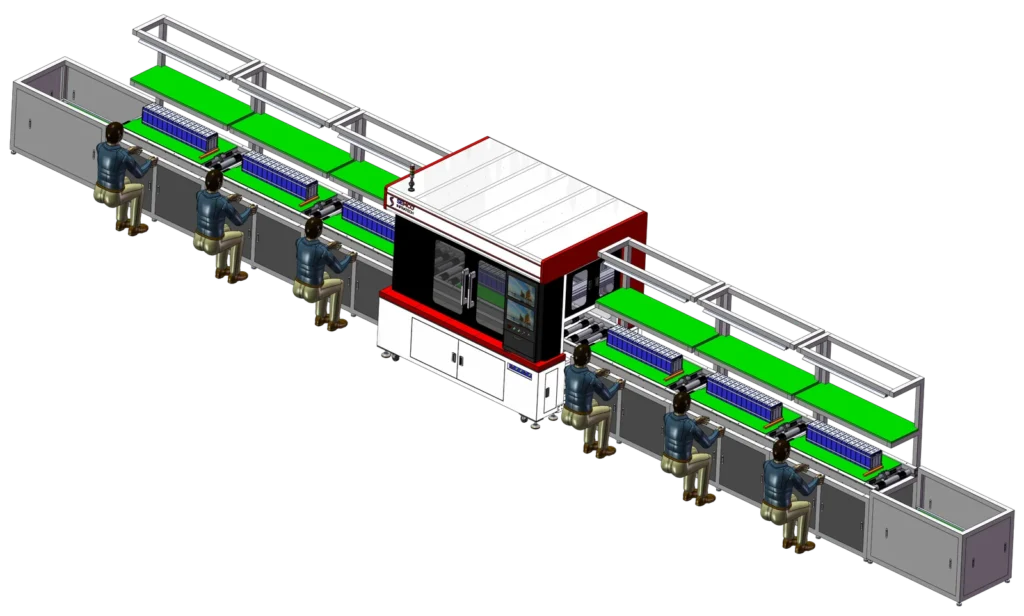

1 Terminal Semi-automated assembly line

Semco’s 1-terminal semi-automated assembly line presents a smart and scalable entry point into automated lithium battery production. Featuring a high-precision in-line laser welding machine as its central automated station, the system is complemented by offline stations for cell preparation, compression, cleaning, and post-weld inspection—strategically arranged along a synchronized conveyor framework. This hybrid approach optimizes capital investment while ensuring process integrity and consistent output quality. Ideal for producers transitioning from manual setups to semi-automation, the solution offers modular expandability, minimal footprint, and seamless integration into existing production environments.

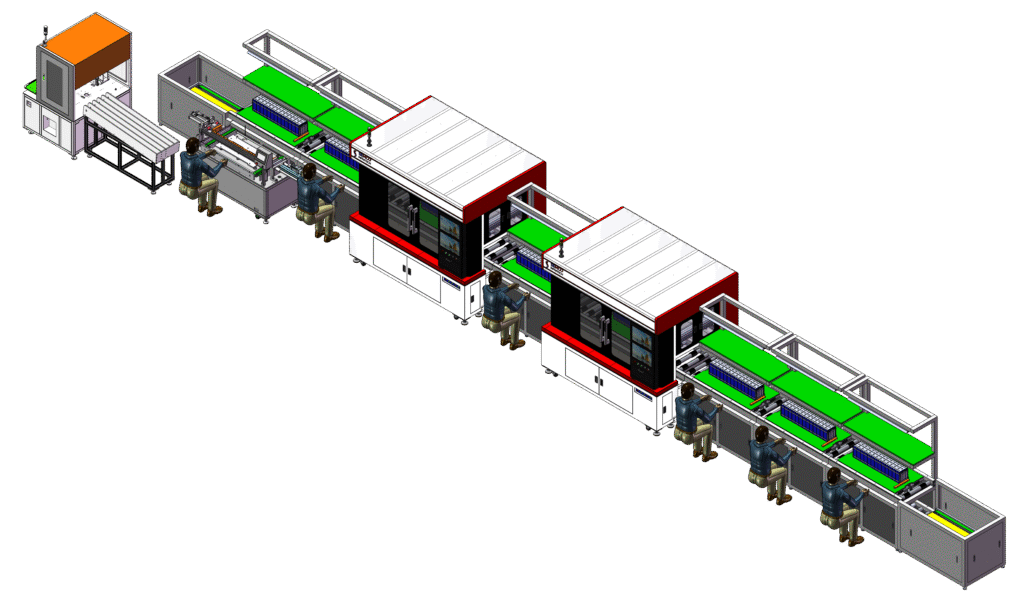

2 Terminal Semi-automated assembly line

Semco offers an optimal balance of advanced automation and cost-efficiency, making cutting-edge battery assembly accessible to a wider range of producers. Its ingeniously compact design, coupled with integrated precision technologies, delivers high throughput for semi-automated production lines, perfectly suiting the needs of evolving manufacturing scales, from pilot lines to mid-volume product.

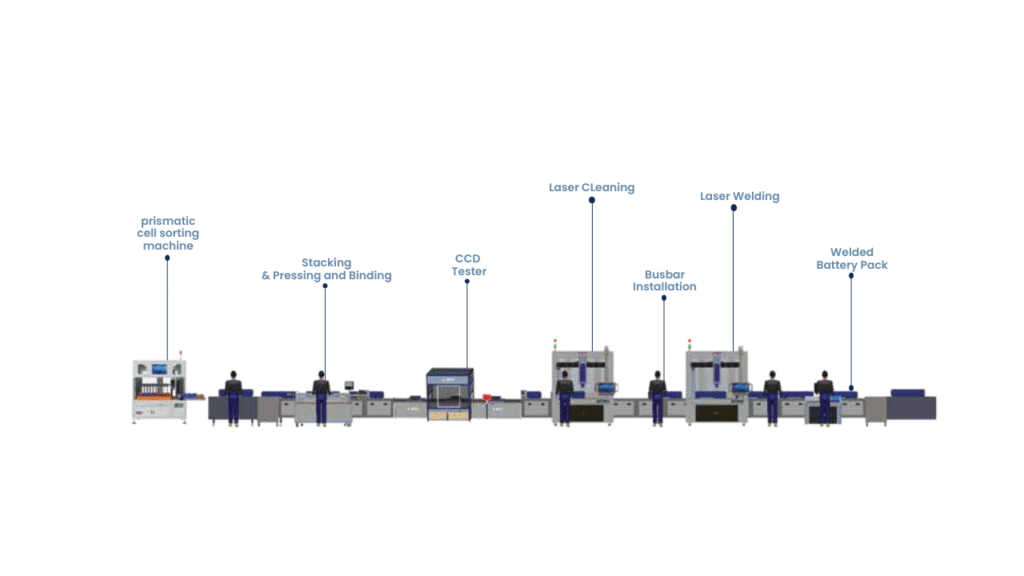

3 Terminal Semi-automated assembly line

Semco’s 3-terminal semi-automated assembly line delivers a refined balance of speed, precision, and modular flexibility for lithium battery module production. Building upon the 2-terminal configuration, this advanced variant features dedicated terminals for polarity detection and laser cleaning, ensuring greater process accuracy, parallel processing capability, and reduced cycle time. With an in-line laser welding machine at its core and intelligently arranged offline stations interconnected via a precision-powered conveyor system, this solution enhances throughput without compromising traceability or consistency. Ideally suited for growing manufacturers scaling toward higher volumes, it offers a future-ready platform adaptable to evolving product designs and production targets.

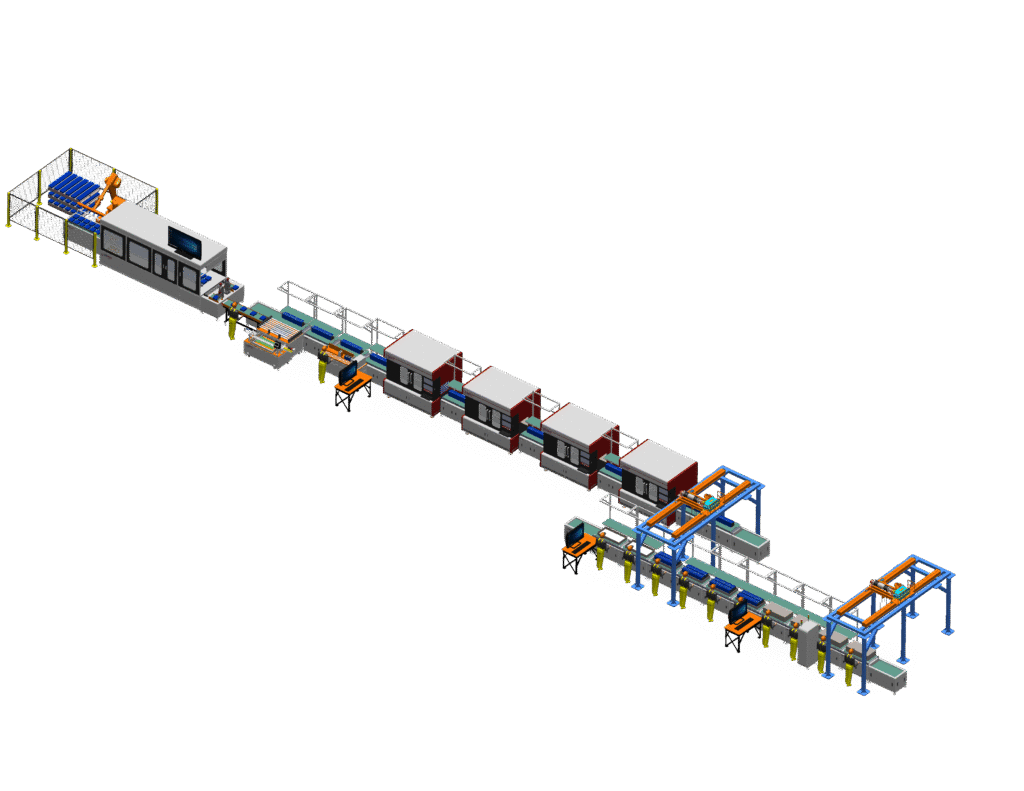

BESS Automatic assembly line

Our automated assembly redefines efficiency and precision in Energy Storage System (ESS)

assembly. Designed for high-volume production, it ensures exceptional throughput and superior yield rates through advanced automation and real-time monitoring. This cutting-edge solution is engineered to meet the rigorous demands of modern energy storage manufacturing, enabling scalable production with unparalleled consistency and reliability for next-generation battery packs.