Introduction of BESS Container Testing

Battery Energy Storage Systems (BESS) have become the backbone of modern renewable energy infrastructure. As the demand for large-scale energy storage solutions grows, manufacturers face increasing pressure to deliver systems that are not only efficient but also safe and reliable. While individual battery packs and racks undergo rigorous testing during production, the true test of a BESS system’s readiness comes at the container level. This is where Container Assembly Line testing plays a pivotal role in ensuring that integrated systems perform flawlessly in real-world conditions.

Understanding the Gap Between Component and System Testing

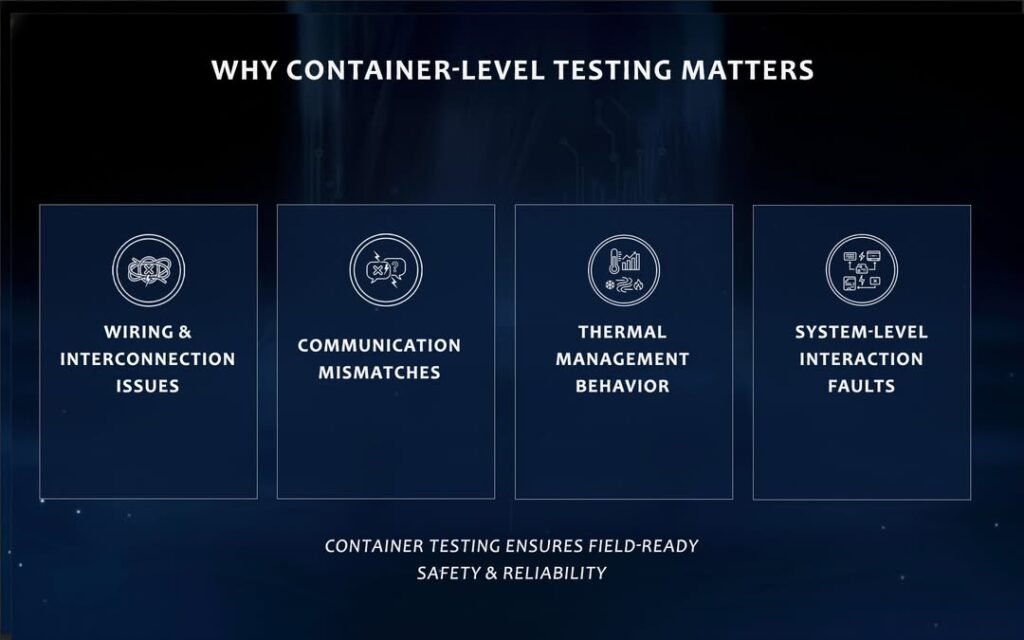

When battery racks are tested individually, they may perform perfectly within controlled parameters. However, once these racks are assembled into a complete container system, new challenges emerge. Wiring configurations, communication protocols between multiple units, thermal distribution patterns, and complex system-level interactions create variables that simply don’t exist at the component level. This is precisely why container-level validation cannot be skipped or substituted with lower-level testing alone.

The Role of Comprehensive Container Testing in Quality Assurance

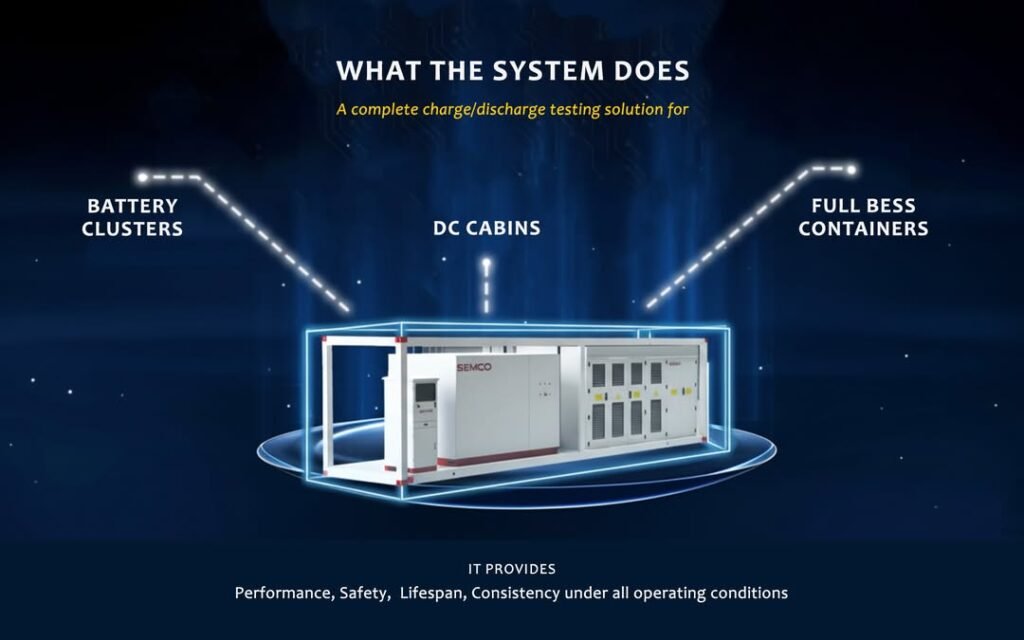

Semco Infratech’s BESS Container Testing System addresses this critical quality control checkpoint by providing all-in-one testing capabilities for both battery clusters and DC cabins. The system performs thorough charge and discharge cycles that simulate actual operational conditions, collecting real-time data on voltage, current, power output, temperature variations, and capacity metrics. This comprehensive approach reveals potential issues such as inter-cluster imbalance and circulating currents that could compromise system performance or safety once deployed.

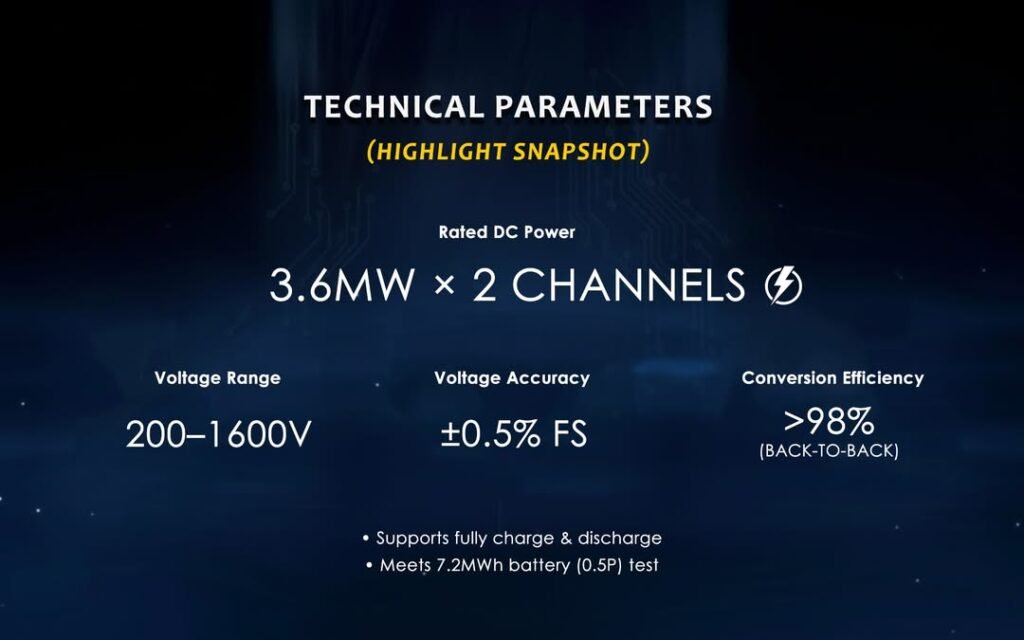

Available in multiple power configurations—2.5MW, 3.2MW, 3.6MW, and 5MW—the testing system accommodates various production scales and BESS specifications. Through full-cycle testing protocols including C-rate performance analysis, capacity verification, and cycle life assessment, manufacturers gain deep insights into each container’s operational characteristics before it leaves the factory floor.

Innovation in Energy-Efficient Testing Technology

One standout feature of Semco Infratech’s solution is its back-to-back testing topology, which represents a significant advancement in sustainable manufacturing practices. This innovative approach allows simultaneous charging and discharging of two DC cabins, creating a closed energy loop that dramatically reduces power consumption during the testing process. For high-volume production facilities, this translates to substantial cost savings and a reduced environmental footprint.

The compact, integrated design offers exceptional flexibility for various factory layouts, supporting both indoor and outdoor installation scenarios. This adaptability ensures that the BESS Container Assembly Line can be seamlessly incorporated into existing production workflows without requiring extensive facility modifications.

Smart Automation for Manufacturing Excellence

Modern BESS production demands precision and traceability at every stage. Semco Infratech’s intelligent auto-test software provides complete process control, automatically recording all test parameters and generating detailed analytical reports. This documentation is invaluable for research and development teams working on product optimization, quality assurance personnel tracking production consistency, and regulatory compliance requirements.

The automated data collection and reporting capabilities significantly improve testing efficiency while reducing the potential for human error in record-keeping and analysis.

Conclusion of BESS Container Testing

As the energy storage industry continues to mature, the importance of thorough container-level validation cannot be overstated. Semco Infratech’s BESS Container Testing System provides manufacturers with the tools necessary to ensure that every container leaving their facility meets the highest standards of safety, performance, and reliability. By addressing the complex interactions that only become apparent at the system level, this testing solution serves as an essential quality checkpoint—protecting both manufacturer reputation and end-user investment in large-scale battery storage infrastructure.