Leading in Production Efficiency

Semco Infratech, a division of the Semco Group, distinguishes itself as a prominent player in lithium-ion battery production, testing, and assembly specializing in automation and digitization.

Semco Infratech operates in the market through key brands like Hynn & Neware. Established to cater to the growing demand for lithium-ion battery assembly equipment, Semco Infratech embodies a legacy of innovation and offers a wide range of products tailored to this sector for over two decades.

About Us

Semco Infratech, a division of the Semco Group, is a leader in lithium-ion battery production, testing, and assembly, specializing in automation and digitization. The company provides cutting-edge solutions like sorting, testing, grading, laser welding, aging machines, IR testers, and OCV testers, ensuring efficient and reliable battery performance. With expertise spanning multiple industries, Semco Infratech delivers innovative solutions to meet the evolving needs of modern technology.

Our Services

Our Clientele

Testimonials

Azad Saini

Assistant Manager-Purchase

Luminous Power Technologies

Innovation and reliability are the hallmarks of Semco Infratech's exceptional service. Their lithium-ion battery testing machines and balancers have played a pivotal role in advancing our technological capabilities.

Manjeet Singh

Assistant Manager

Okaya Power Group

We have been working with Semco Infratech for several years, and they have consistently provided us with top-quality precision test and measurement equipment.

Devendra Chawla

MD & CEO

GreenCell Mobility

Semco Infratech's dedication to delivering high-value services and innovative technologies has greatly contributed to the success of our projects.

Rohit Kumar

Energy Storage Engineer

Thermax Limited

As a global leader in energy solutions, we rely on partners like Semco Infratech to provide us with cutting-edge equipment. They are fast, simple, and precise at their work.

Neha Sharma

Co-Founder, Gosporty

Semco Infratech has been an invaluable partner in our pursuit of excellence. Their commitment to delivering state-of-the-art precision test and measurement equipment has significantly enhanced our operational efficiency.

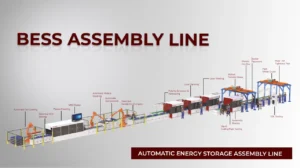

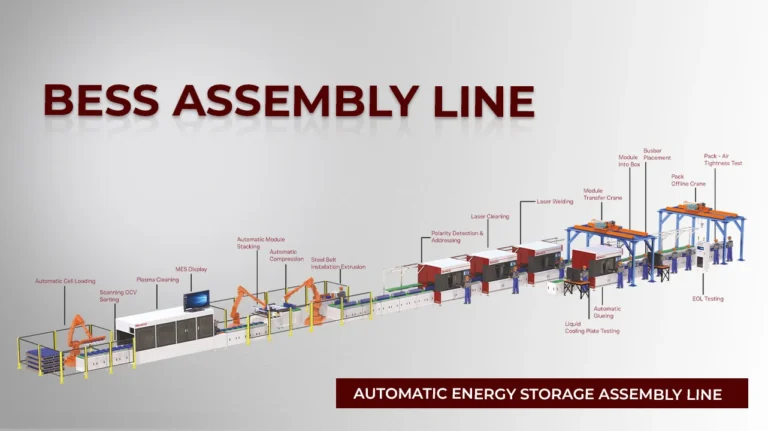

BESS Assembly Line: The Foundation of Scalable Energy Storage Manufacturing

As battery energy storage systems transition from demonstration projects to...

Read MoreUnderstanding Liquid Cooling in Energy Storage Systems

Why Liquid Cooling Matters Effective strategies for liquid cooling in...

Read MoreAutomatic Energy Storage Assembly Line: From Cell to Containerized BESS Solutions

Automatic Energy Storage Assembly Line: From Cell to Containerized BESS...

Read MoreBESS Container Testing System: Ensuring Safe, Reliable Container-Level Energy Storage

Introduction of BESS Container Testing System As grid-scale energy storage...

Read MoreBlogs

BESS Assembly Line: The Foundation of Scalable Energy Storage Manufacturing

Understanding Liquid Cooling in Energy Storage Systems

Automatic Energy Storage Assembly Line: From Cell to Containerized BESS Solutions

BESS Container Testing System: Ensuring Safe, Reliable Container-Level Energy Storage

Why BESS Container Testing is Critical for Energy Storage Manufacturing

Prismatic vs Cylindrical Batteries: Which Works Best for EV & BESS?

Events

The Smarter E India 2025

Renewable Energy Expo 2025

Bharat Mobility 2025

We Have Innovative Solutions For Future

Global Pioneers

Energizing the future with precision energy solutions since 2006.

Innovation Allies

Partnered with industry titans, Semco sparks brilliance in every circuit.

Tailored Excellence

Your energy needs met worldwide—Semco Infratech—Providing Precision and Perfection With Pride.

Contact Us

For any inquiries, questions, or recommendations, please call:

+91 11-4264-1452 or fill out the following form

Frequently Asked Questions (FAQs)

An automatic lithium battery assembly line is a fully integrated system that streamlines the production of lithium-ion batteries. It uses advanced automation technologies to handle processes such as cell sorting, welding, stacking, packaging, testing, and quality inspection. By reducing manual intervention, it ensures higher efficiency, consistent quality, and faster production rates—making it ideal for large-scale battery manufacturing.

A lithium battery assembly line typically includes:

Cell Sorting Machines – for classifying cells by capacity, voltage, and resistance.

Laser Welding Systems – for precise and reliable connections.

Stacking & Assembly Machines – for prismatic, pouch, or cylindrical battery modules.

Battery Management System (BMS) Integration Equipment – for monitoring safety and performance.

Aging & Formation Equipment – for charging/discharging cycles to stabilize battery performance.

End-of-Line (EOL) Testing Systems – for quality validation before delivery.

Semco provides end-to-end battery assembly solutions with all these components seamlessly integrated.

A prismatic battery assembly line is specifically designed for manufacturing prismatic cells, which are rectangular in shape and widely used in electric vehicles (EVs), energy storage systems, and portable electronics. This line includes equipment for cell stacking, case assembly, laser welding, electrolyte filling, sealing, and testing. Semco’s prismatic assembly lines are tailored for high precision and scalability to meet the growing EV and ESS demand.

A Battery Energy Storage System (BESS) assembly line differs from a standard battery assembly line in its scale, design, and integration requirements. While a regular line focuses on cell or module-level assembly, a BESS line is designed for large-scale module and pack assembly, including:

High-capacity prismatic/pouch/cylindrical cells

Battery racks and cabinet assembly

Thermal management systems integration

Advanced BMS setup for grid applications

Safety and reliability testing under energy storage standards

Semco provides custom BESS assembly solutions that support utility, industrial, and renewable energy projects.

An energy storage assembly line is used to manufacture battery packs and modules specifically designed for renewable energy integration, grid stabilization, telecom backup, and industrial applications. These lines ensure high safety, durability, and performance standards, making them essential for the rapid growth of the Energy Storage System (ESS) market.

Battery laser welding is a high-precision welding technique used to join metal components in lithium-ion batteries, such as tabs, busbars, and casing parts. It is important because it provides:

High-strength and reliable joints

Minimal heat damage to cells

Improved safety and performance

Consistent quality for mass production

Semco’s advanced laser welding systems ensure precise, efficient, and safe connections in battery manufacturing.

Yes, laser welding is suitable for prismatic, cylindrical, and pouch batteries, though the welding method and parameters vary depending on battery design and material type. For high-energy density and safety-critical applications like EVs and ESS, laser welding is the preferred method due to its accuracy and durability.

Absolutely. Semco Infratech specializes in providing customized lithium battery assembly line solutions tailored to specific requirements such as battery type (cylindrical, prismatic, pouch), capacity range, production volume, and automation level. From cell testing and sorting machines to fully automated BESS assembly lines, Semco delivers end-to-end solutions to help manufacturers scale efficiently and maintain high-quality standards.

Semco designs and manufactures battery assembly lines, BESS container production lines, battery testing equipment, high-voltage testers, cell grading systems, and automation solutions for lithium-ion battery production.

Yes. Semco offers complete solutions—from cell grading, sorting, welding, pack assembly, BMS testing, to EOL testing and BESS container integration.

Yes. Semco provides 3 major production lines:

- Cylindrical battery assembly line

- Prismatic battery assembly line

- Pouch cell testing & integration (via Neware & Repower systems)

A BESS Container Assembly Line is a production system that integrates battery racks, high-voltage packs, cooling systems, fire safety systems, and EMS controls inside ISO containers for energy storage applications.

Semco provides:

- BESS Container EOL Testers

- High Voltage Battery Pack Testers

- 1650V Battery Testing Systems

- Rack Testing Systems

These ensure safety, insulation resistance, leakage prevention, and performance.

- Renewable energy companies (solar + storage)

- Utility grid operators

- Telecom & data centers

- Commercial & industrial (C&I) users

- Microgrid and off-grid projects

A High Voltage Battery Pack Tester checks voltage, current, IR, HV insulation, and safety compliance for battery packs ranging from 100V to 1650V.

An EOL (End-of-Line) Tester validates final battery performance—including safety, communication signals, CAN, temperature, IR, withstand voltage, and overall pack functionality.