In the high-stakes world of lithium-ion battery manufacturing, where safety and performance are paramount, the Helium Detection inspection process stands as a critical guardian. It bears the crucial responsibility of ensuring the absolute sealing and inherent safety of every battery. Given that the electrolyte within a lithium-ion battery is highly corrosive and flammable, any breach in its seal can have catastrophic consequences. A leak not only severely degrades battery performance and lifespan but also poses extreme hazards, including short circuits, fires, and even explosions. The helium inspection process acts as a sophisticated early warning system, capable of detecting even the minutest leaks accurately and promptly, thereby providing an unyielding assurance of battery quality and safety.

Exploring the Principle of Helium Detection

At its core, helium detection relies on a specialized instrument: the helium mass spectrometer leak detector. This device utilizes helium as a tracer gas for its unparalleled ability to pinpoint leaks. But why helium? The choice is driven by a unique set of advantages:

- Chemical Stability: Helium is an inert gas, meaning its chemical properties are extremely stable. It does not react with any of the battery’s internal components, ensuring no adverse effects on battery performance or longevity.

- Small Molecular Size and High Diffusivity: Helium molecules are exceptionally small and possess high diffusivity. This allows them to quickly penetrate even the most minuscule leaks or microscopic gaps, making helium an ideal choice for detecting tiny imperfections that other methods might miss.

- Low Atmospheric Content: The concentration of helium in ambient air is remarkably low. This minimal background interference ensures that the test results are highly accurate and reliable, as the detected helium signal is almost exclusively attributable to a leak.

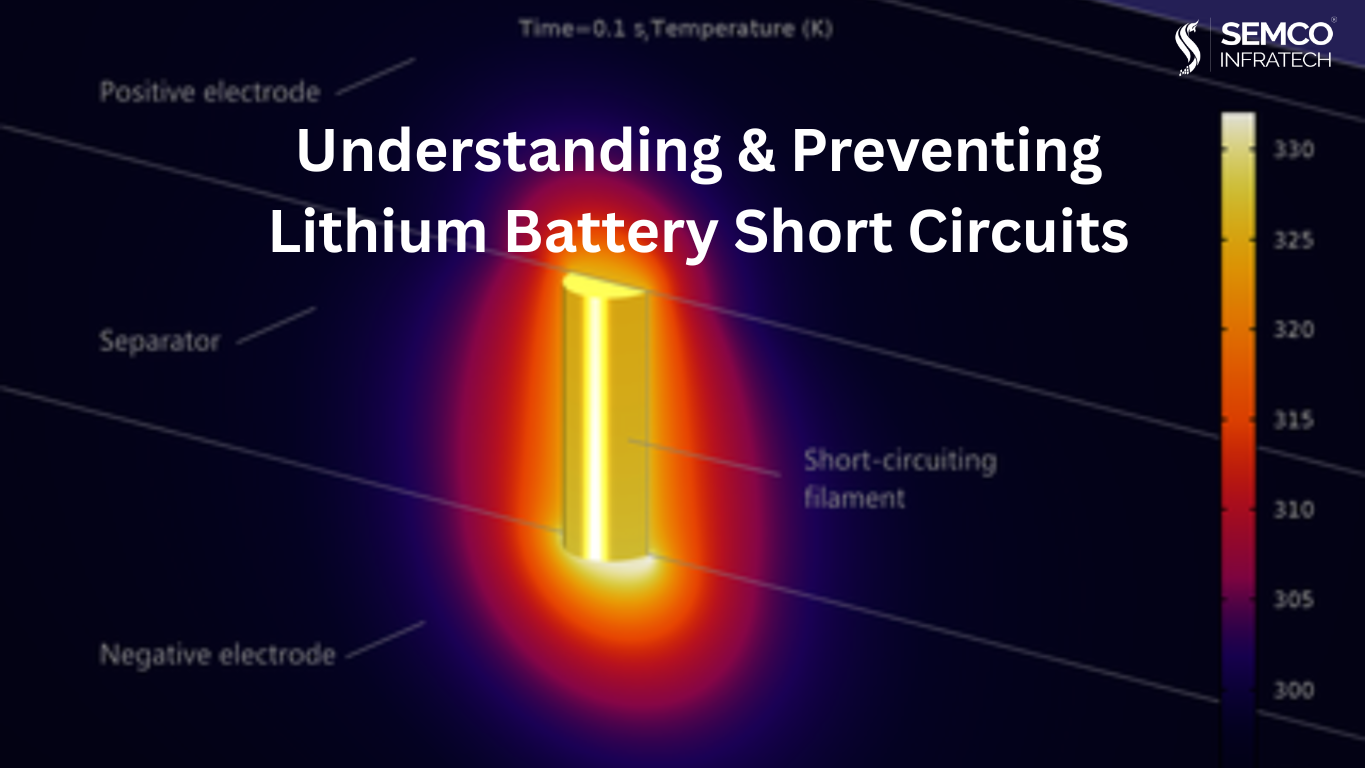

The operation of a helium mass spectrometer leak detector can be likened to a “precision detection journey” in the microscopic world. When a battery undergoes testing, helium is either introduced into its interior or the surrounding environment, depending on the specific test method. Should there be even a microscopic leak in the battery, helium molecules, owing to their small size and high diffusivity, will swiftly diffuse out through the breach.

This is where the helium mass spectrometer leak detector springs into action. Its internal ion source emits electrons. These electrons, accelerated by an electric field, collide with the diffused helium molecules, causing them to ionize into helium ions. Under the combined influence of electric and magnetic fields, these helium ions travel along a specific, precise trajectory—a delicate “dance” in the microscopic realm. Finally, these helium ions are collected, forming a detectable helium ion flow. By accurately measuring the intensity of this helium ion flow, the leak detector can precisely determine not only the presence of a leak but also its size and exact location. In essence, the helium mass spectrometer leak detector functions as a microscopic “detective,” expertly pinpointing any potential leak.

The Vacuum Pressure Method: A High-Precision Approach

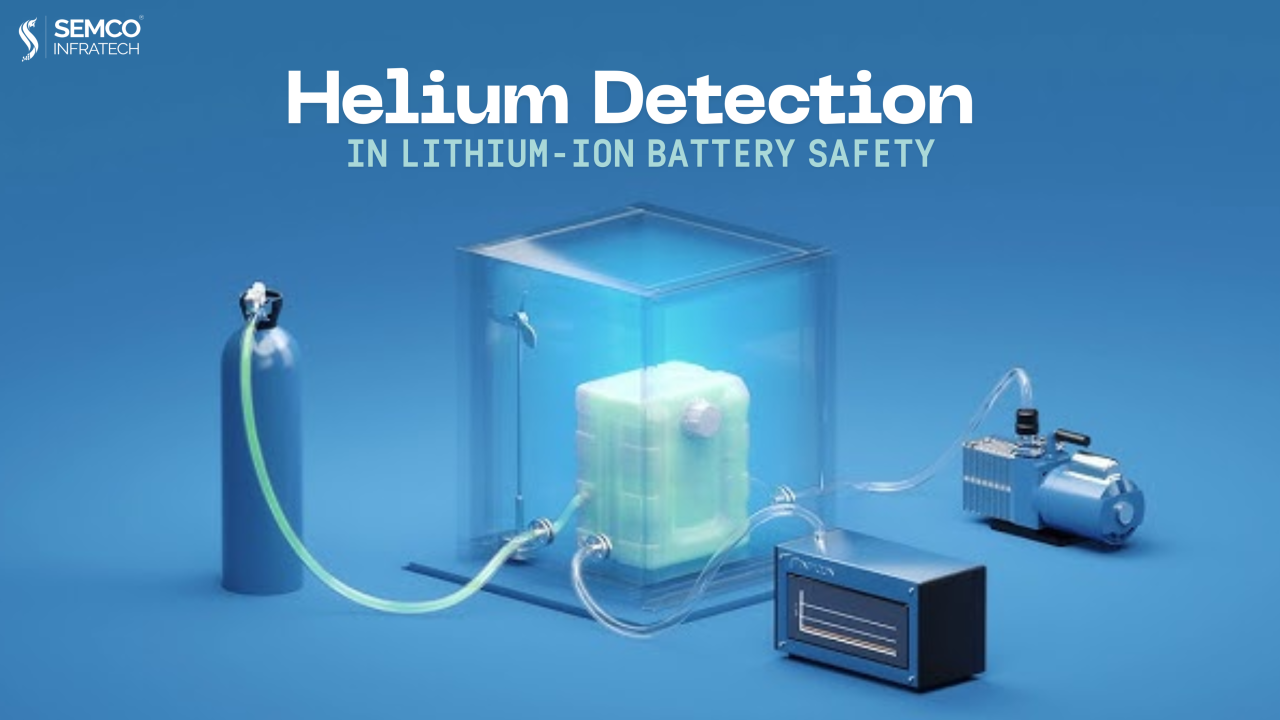

In the manufacturing of lithium-ion batteries, the most commonly employed helium detection technique is the vacuum pressure method. While its operation can be intricate, it offers unparalleled precision in leak detection.

The process begins by placing the battery to be tested entirely within a vacuum sealed chamber. This chamber acts as a “mysterious detection cabin,” providing an isolated and stable environment for the test. This sealed chamber is intricately connected to an auxiliary vacuum system and the helium mass spectrometer leak detector, forming a meticulously coordinated “detection team.” The inflation interface of the battery under test is routed out of the vacuum sealed chamber via a connecting pipe and then linked to a helium source.

When the test commences, the auxiliary vacuum system rapidly evacuates the air from the sealed chamber, establishing a vacuum environment. Subsequently, helium is injected into the battery through the connecting pipe. If the battery has a leak, the helium will quickly escape through the breach, enter the vacuum sealed chamber, and then be drawn into the helium mass spectrometer leak detector. The leak detector’s ability to detect this incoming helium allows for an accurate determination of whether the battery has a leak and, if so, its extent.

The advantages of the vacuum pressure method are significant. Its detection sensitivity is exceptionally high, allowing it to identify extremely minute leaks. Even leaks with very low leak rates are unlikely to escape its “fiery eyes.” Furthermore, this method can assess the leakage rate of batteries under any operational pressure, providing a true and accurate reflection of the battery’s actual leakage status. This robust data forms a reliable foundation for comprehensive battery quality assessment.

Key Control Points: Ensuring Accuracy and Reliability

In the helium inspection process, several key control points must be meticulously managed. These points directly impact the accuracy and reliability of the test results and are decisive in guaranteeing overall battery quality.

Parameter Setting of Helium Inspection Equipment

The various parameters of the helium inspection equipment, such as detection pressure, detection time, and helium flow rate, require precise adjustment and optimization. These settings must be tailored to factors like the battery type, size, design requirements, and production process.

Consider detection pressure: if set too low, some tiny leaks might go undetected, allowing potentially faulty batteries to proceed to the next stage, embedding hidden quality issues. Conversely, if the detection pressure is too high, it could cause unnecessary damage to the battery, compromising its performance and lifespan. Therefore, in actual production, extensive experimentation and data analysis, combined with the specific characteristics of the battery, are essential to determine the optimal detection pressure range. Moreover, regular calibration and verification of equipment parameters are crucial to ensure the equipment consistently operates under optimal conditions, guaranteeing accuracy and consistency in test results.

Environmental Conditions Control

The environmental conditions during the helium detection process are critically important. Factors such as ambient temperature, humidity, and even the background helium content in the air can significantly influence test outcomes.

Excessive ambient temperature or extreme cold can cause thermal expansion and contraction of battery materials, affecting the battery’s seal and leading to deviations in test results. High humidity can introduce moisture into the battery, potentially reacting with the electrolyte, impacting battery performance, and interfering with test data. If the helium content in the test environment is too high, it creates elevated background noise, making it difficult for the leak detector to accurately isolate the actual leakage signal from the battery itself, potentially leading to false positives.

To ensure the reliability of test results, the temperature and humidity of the test environment must be maintained within appropriate ranges. Furthermore, the test area should be well-ventilated to minimize environmental helium content. Typically, the test environment temperature is controlled between 20℃ – 25℃, relative humidity between 40% – 60%, with regular monitoring of ambient helium content.

Testing Process Specification

The meticulous specification of the testing process must not be overlooked. Every step, from battery loading and positioning to testing, unloading, and data recording, must strictly adhere to established operating procedures.

During battery loading, ensuring accurate positioning is vital to prevent detection inaccuracies caused by positional deviations. Throughout the test, operators must closely monitor the equipment’s operational status and test data. Any abnormality should prompt an immediate halt to the equipment for inspection and resolution. After the test, accurate recording of all test data—including test time, results, and battery serial numbers—is essential for subsequent quality traceability and data analysis. Finally, tested batteries must be properly sorted and handled, with qualified and unqualified units stored separately to prevent mix-ups.

Addressing Abnormal Situations

Encountering abnormal test results is a common occurrence in helium inspection. When the results indicate a battery leak, the underlying cause is often not straightforward and requires careful analysis.

On one hand, the anomaly might stem from defects within the battery itself, such as loose shell welding or uneven sealant application, leading to a genuine leak. In such cases, a detailed inspection and analysis of the unqualified battery are necessary to pinpoint the exact leak location and cause. Remedial actions depend on the severity: minor leaks might be repairable through re-welding or sealant application, while more severe issues necessitate immediate scrapping of the battery to mitigate potential safety risks.

On the other hand, abnormal test results can also be caused by external factors, such as detection equipment failure or environmental interference. For instance, a malfunctioning sensor in the helium mass spectrometer leak detector can lead to inaccurate data. Similarly, a sudden surge of high-concentration helium in the detection environment can cause the leak detector to misinterpret the signal. When external factors are suspected, the detection equipment should undergo a comprehensive inspection and calibration to ensure its normal operation. Calibrating the leak detector with a standard leak hole can verify its detection accuracy. Simultaneously, the detection environment should be checked for potential sources of interference. If helium leaks or other issues are found in the environment, immediate measures should be taken to clean and eliminate them before retesting the battery.

Equipment failure is another challenge that may arise during helium inspection. Helium inspection equipment is a complex system, and a malfunction in any component can disrupt its normal operation. Common equipment failures include mechanical pump failure, molecular pump failure, or mass spectrometer failure.

- Mechanical pump failure might manifest as an inability to start, abnormal running sounds, or smoke from the exhaust port. When these occur, initial checks should include power supply voltage, switch status, winding integrity, and motor overheating. Simple issues like motor overload can often be resolved by restarting or adjusting the load. However, severe problems like motor damage will require a replacement.

- Molecular pump failure might be indicated by a “TMP display 0,” an extinguished acceleration indicator light, or an illuminated fault light. Addressing these issues requires checking the fore-stage pressure, inspecting for damage to the molecular pump’s blades or rotors, verifying fuses on the circuit board, confirming correct circuit board switch settings, and checking fan operation. Solutions will vary based on the specific cause, such as adjusting pressure, replacing damaged parts, or repairing the circuit board.

- Mass spectrometer chamber failure may present as an inability of the filament to start normally or fluctuating background signals. If the filament doesn’t start, the ion source should be checked for damage, and the ion source aviation socket and terminal for open circuits. Replacement of the ion source or relevant circuit repair may be necessary. Abnormal background signal fluctuations could point to amplifier failure or contamination of the mass spectrometer chamber. These issues require professional maintenance personnel for diagnosis and repair.

Conclusion

The helium detection process is an indispensable quality control measure in lithium-ion battery production. Its meticulous application, coupled with a thorough understanding of the underlying principles and diligent attention to critical control points, ensures that only perfectly sealed and safe batteries proceed to market. The ability to accurately identify and address leaks, whether due to battery defects or equipment malfunctions, is paramount for safeguarding product quality, mitigating safety risks, and ultimately building consumer trust in lithium-ion battery technology. As battery technology continues to evolve, the precision and reliability of helium leak detection will remain a cornerstone of manufacturing excellence and safety assurance.