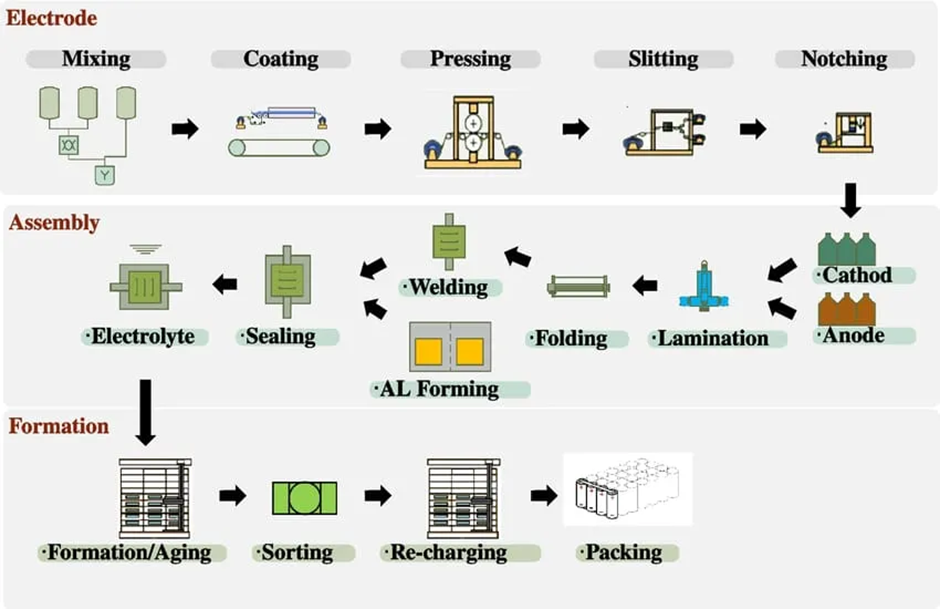

In the evolving EV battery manufacturing process, two steps—chemical formation and capacity sorting—stand out as the backbone of battery reliability, safety, and performance. These steps, powered by precise battery formation equipment and battery grading machines, play a critical role in the lithium-ion battery production line.

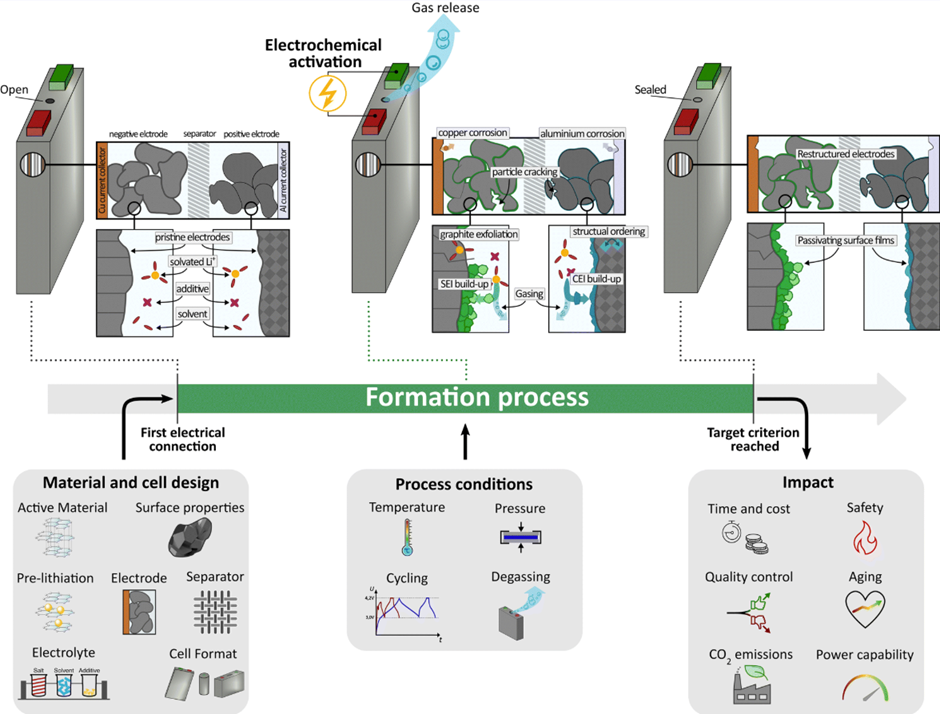

The Chemical Formation Process

Chemical formation marks the electrochemical birth of a battery. It’s a controlled process involving slow charging and discharging using battery formation equipment that:

- Promotes uniform SEI (Solid Electrolyte Interphase) layer formation

- Ensures long-term battery stability and cycle life

- Uses pressure to expel gas and maintain structural consistency

- Involves electrolyte refilling to restore balance

The quality of this process directly affects battery performance, lifespan, and safety.

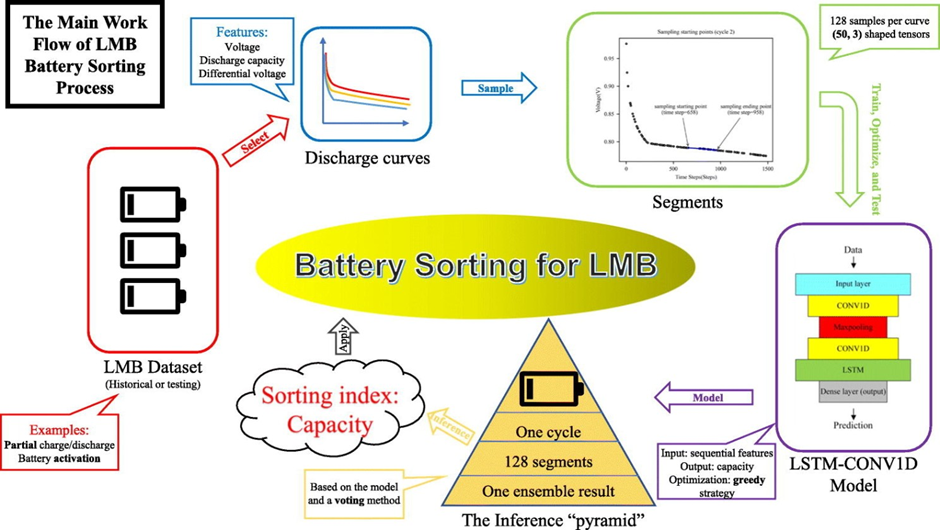

Capacity Sorting Explained

Once the cells complete formation, they undergo a stringent capacity sorting process. The battery grading machine classifies cells based on their actual capacity and performance parameters:

- OCV (Open Circuit Voltage) at high and room temperatures

- Charge/discharge behaviour under controlled conditions

- Internal resistance and self-discharge rate (via K-value)

- Cell matching for consistent pack performance

Only cells that meet tight tolerance levels move ahead in the lithium-ion battery production line, ensuring pack uniformity.

Precision Is Non-Negotiable

Modern battery formation equipment and battery grading machines operate with <0.01% accuracy in current and voltage readings, minimizing defects and maximizing performance. Precision tools are the key to scalable, high-quality EV battery manufacturing.

Conclusion

Chemical formation and capacity sorting are not just steps—they are safeguards. When executed with the right technology, they empower manufacturers to deliver efficient, high-performance, and safe batteries across the globe.