As the world rapidly shifts toward renewable energy sources like solar and wind, a major challenge emerges: intermittency. The sun doesn’t always shine, and the wind doesn’t always blow. This is where Battery Energy Storage Systems (BESS) step in, acting as the essential bridge between clean energy generation and a stable, reliable power grid. BESS stores excess energy during peak production and releases it when demand is high or generation is low, a process that is crucial for a modern grid.

The BESS manufacturing trends are evolving at a rapid pace to meet this growing demand. We’re seeing exciting innovations that are making renewable energy more practical and cost-effective than ever before.

Key Trends in BESS Manufacturing and Technology

1. The Dominance of Lithium-Ion (and its Future Competitors)

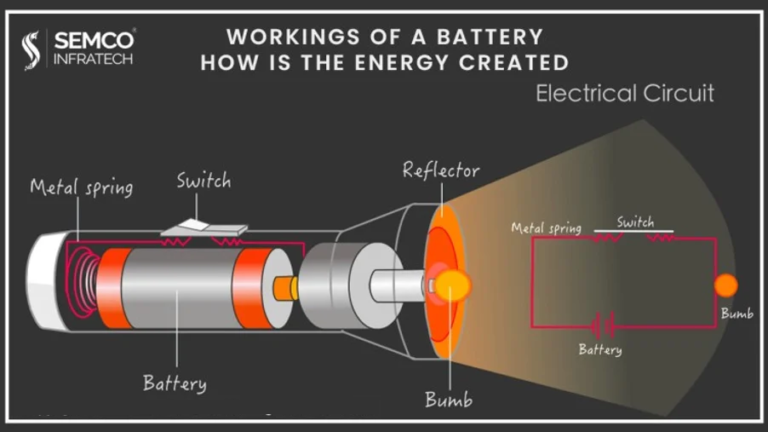

For now, lithium-ion batteries remain the undisputed champion of the BESS market. Their high energy density, efficiency, and dropping costs, largely driven by the electric vehicle (EV) industry, make them the go-to choice for grid-scale battery assembly. However, this isn’t the whole story. As we look ahead, we see a focus on improving lithium-ion batteries and exploring new chemistries.

- Improved Lithium-Ion: Manufacturers are focusing on enhancing lithium-ion technology with innovations like silicon anodes and solid-state electrolytes to improve energy density and safety.

- Alternative Chemistries: Other battery types are gaining traction for specific applications. Sodium-ion batteries, made from more abundant and cheaper materials, are a promising, more sustainable option. Flow batteries are also being developed for long-duration storage, offering a solution for applications that need to store energy for many hours or even days.

2. Smart and Automated Assembly

The demand for BESS is skyrocketing, and manufacturers are turning to advanced technology to scale production efficiently. Automation and artificial intelligence (AI) are becoming central to the grid-scale battery assembly process.

- Robotics and Automation: Automated assembly lines with robotic arms are now standard, ensuring precision, speed, and consistency in the manufacturing process. This not only boosts output but also improves the quality and safety of the final product.

- AI-Powered Management Systems: The value of a BESS isn’t just in the hardware. Sophisticated software, often powered by AI and machine learning, is being integrated into battery management systems (BMS). These intelligent systems can predict energy demand, optimize charging and discharging cycles to extend the battery’s lifespan, and provide real-time monitoring and predictive maintenance.

3. The Rise of Hybrid and Second-Life Systems

The industry is moving toward more integrated and sustainable solutions. Instead of a single, one-size-fits-all approach, we’re seeing two key trends emerge.

- Hybrid Systems: A new trend is the development of hybrid energy storage systems (HESS) that combine different battery types. For example, a system might use lithium-ion batteries for short, rapid bursts of power while a flow battery handles long-duration energy storage. This allows for greater flexibility and cost-effectiveness.

- Second-Life Batteries: A big step toward a circular economy for batteries is the repurposing of used EV batteries. Even after their performance for vehicles degrades, these batteries often have enough capacity left for stationary applications like renewable energy storage. Giving these batteries a “second life” reduces waste and lowers the overall cost of BESS.

4. Policy, Investment, and a Global Push

The growth of BESS manufacturing isn’t happening in a vacuum. Governments and private entities around the world are actively investing in this technology.

- Government Incentives: Policies and financial incentives, such as production-linked incentive (PLI) schemes and viability gap funding (VGF), are encouraging local manufacturing and reducing reliance on foreign supply chains.

- Strategic Partnerships: Companies are forming strategic partnerships with battery technology firms to secure supply chains and co-develop new cell chemistries. This collaborative approach is essential for building resilient and efficient manufacturing ecosystems.

The future of energy is undeniably clean, and BESS are the key to unlocking its full potential. The trends in BESS manufacturing—from new battery chemistries to smart automation—are paving the way for a more reliable, sustainable, and powerful grid that can support a clean energy future.