A high-precision Battery Management System (BMS) Tester ( Semco SI-Y BMST 1-6S (60A/120A) ) designed for lithium battery protection board testing. This advanced equipment ensures accurate evaluation of functional parameters, improving quality control, R&D testing, and production efficiency.

Cell Aging Machines are designed to stabilize lithium-ion cells through controlled charge and discharge cycles, validating capacity, voltage consistency, and thermal behavior before assembly.

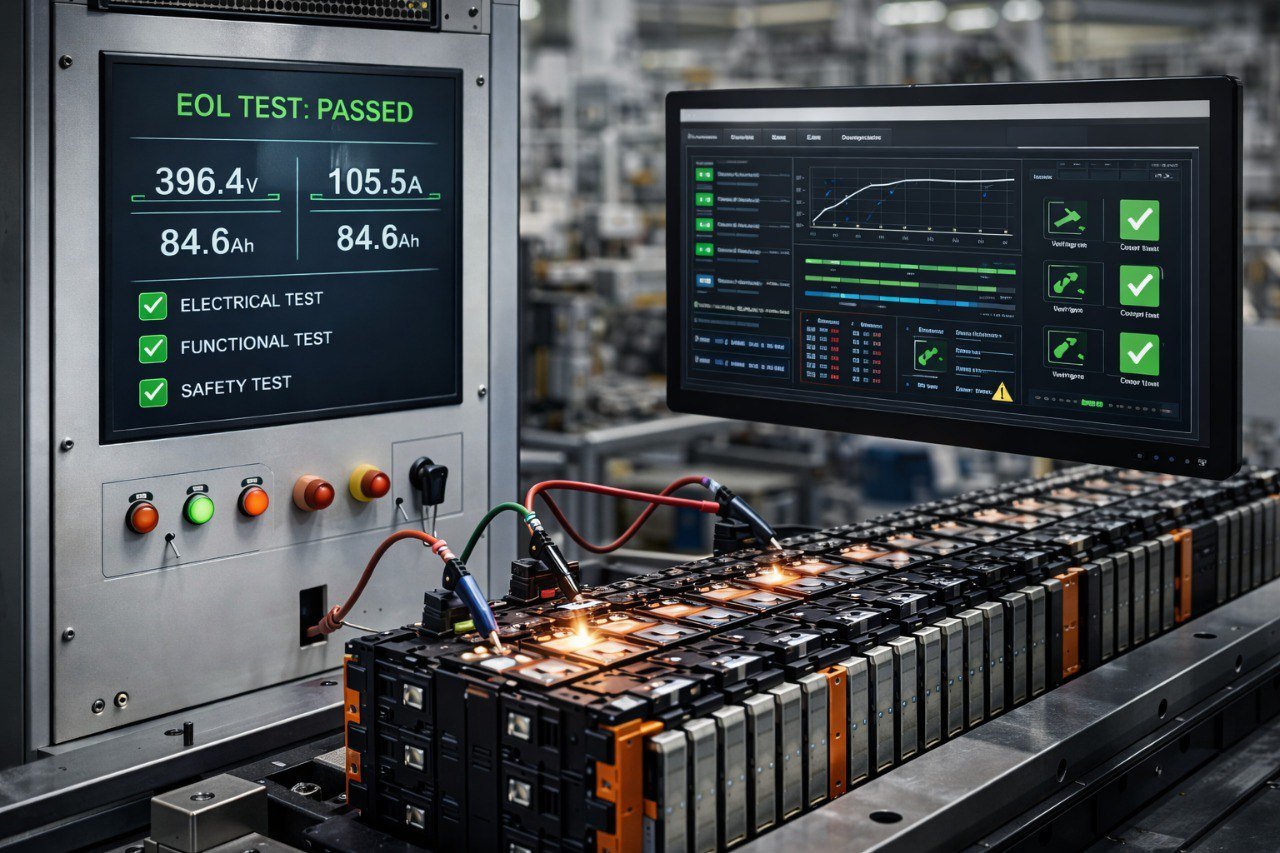

Battery Pack Testers perform complete electrical and safety validation, including voltage, current, insulation resistance, and protection checks.

LOCV Sorting machines measure open circuit voltage to group cells with consistent electrical characteristics, improving performance and lifespan.

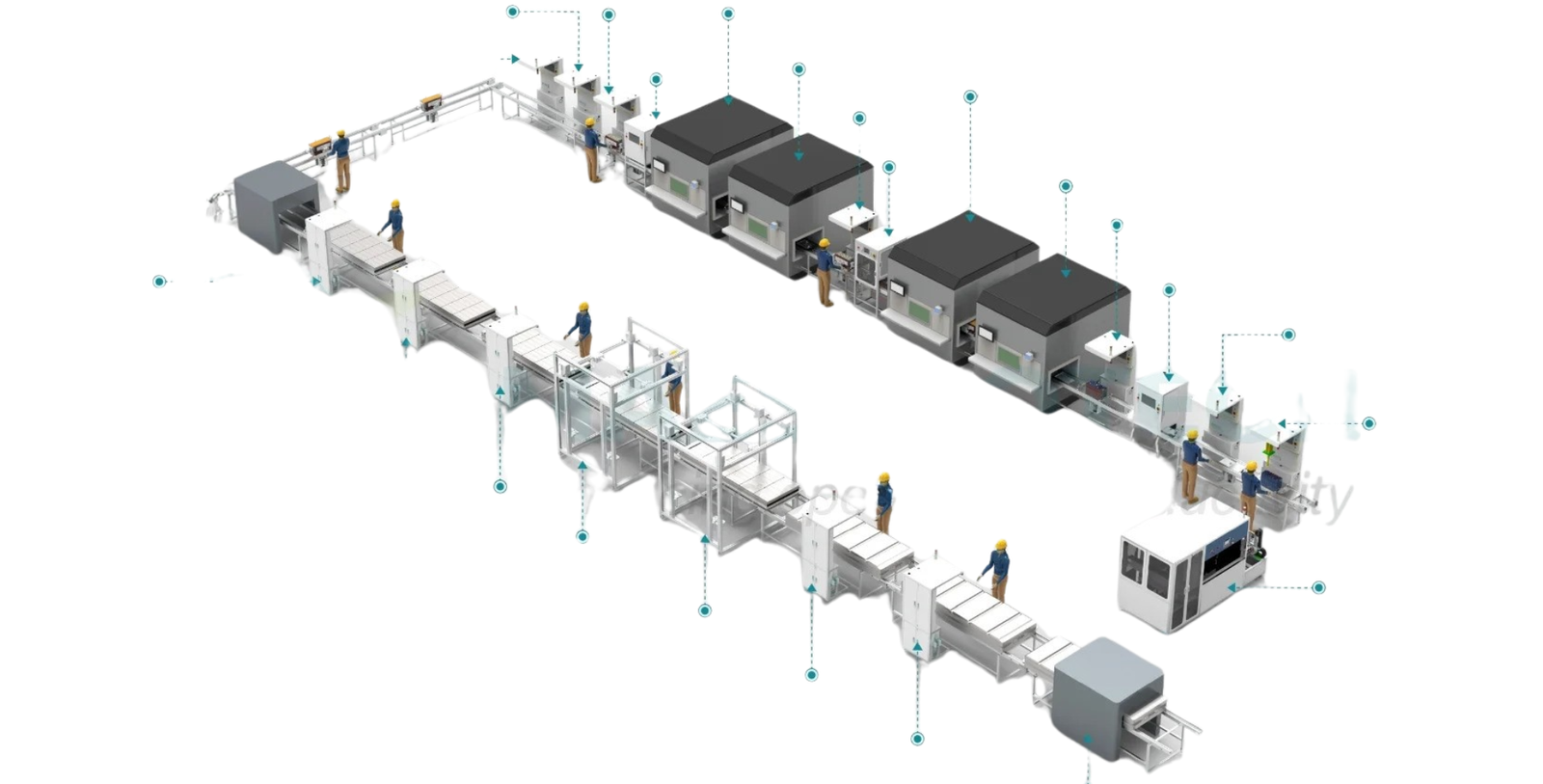

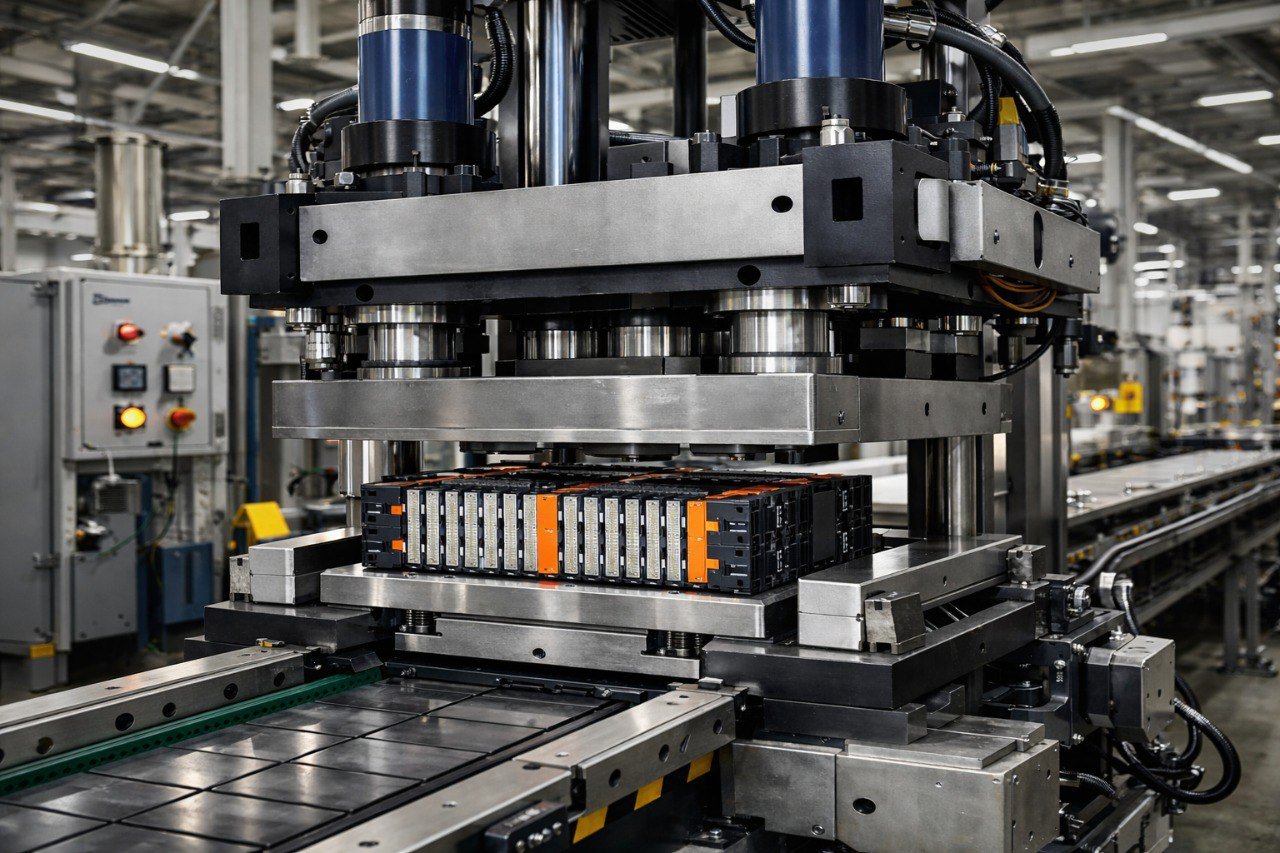

Module Stacking systems precisely align and stack battery cells into mechanically stable modules for downstream processing.

Compression machines apply uniform pressure to enhance module strength, thermal contact, and long-term durability.

Laser Cleaning removes oxides and contaminants from battery tabs and terminals, ensuring clean, high-quality welding surfaces.

Vision-based polarity and CCD inspection detects alignment errors, defects, and missing components early in the process.

Laser Welding machines deliver precise, repeatable, high-strength joints with minimal heat impact.

End-of-Line testing validates electrical, functional, and safety performance before pack integration.

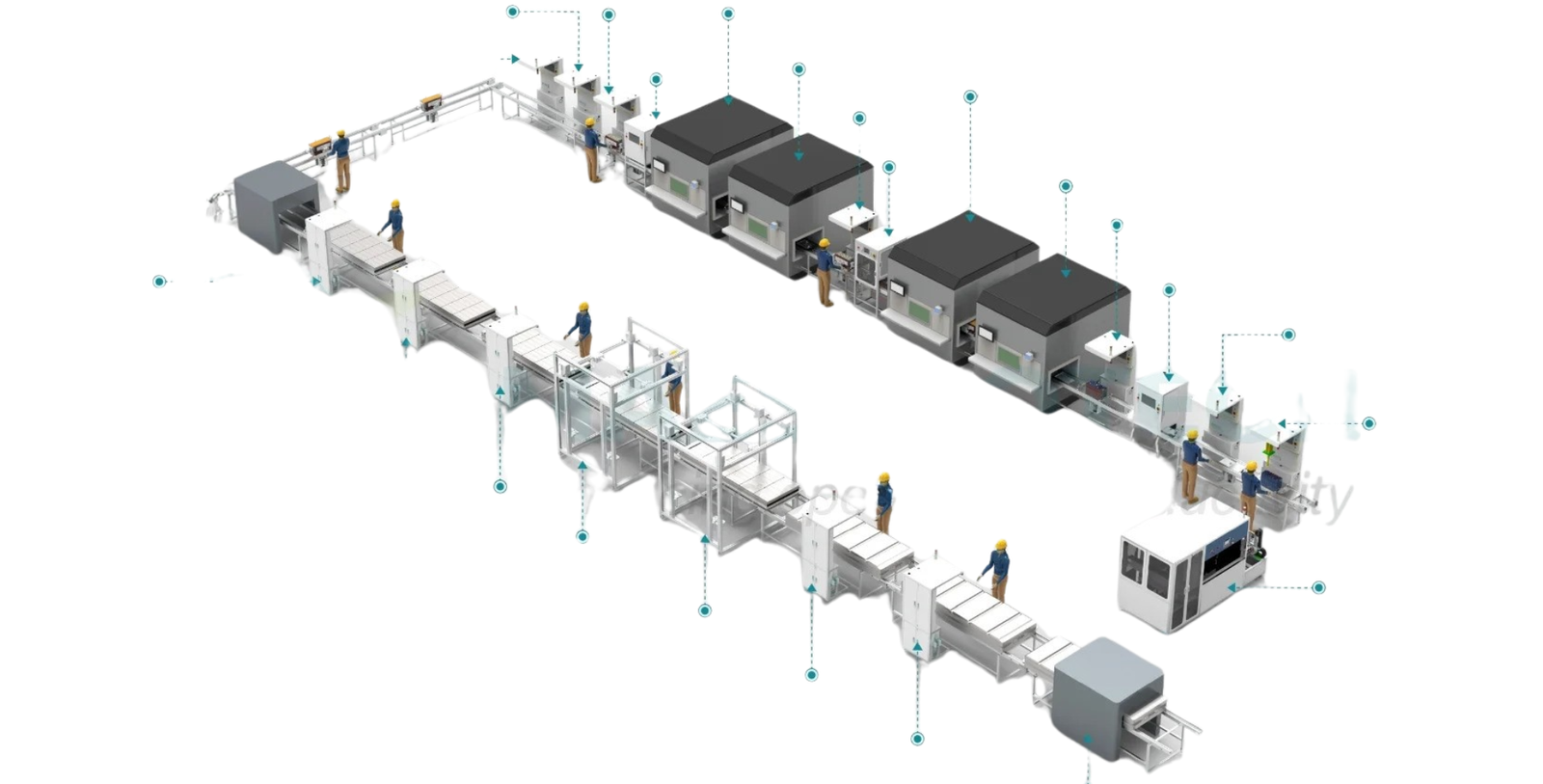

The Pack Line integrates final assembly, enclosure installation, and testing for scalable battery production.

EV battery production, energy storage manufacturing, battery research labs, electronics assembly, and OEM-based fabrication units.

This equipment is designed to support efficient and accurate battery assembly and testing workflows. With durable construction, precision control, and user-friendly operation, it delivers consistent performance for both small-scale and large-scale production environments.

Product Name

Description

The product comes with a dedicated support and service package that includes activation, calibration assistance, and post-installation guidance.

Find quick answers to common questions about our BESS Assembly Line, including automation capabilities, supported battery types, customization options, safety standards, and production scalability.

Reviews

There are no reviews yet.