Step-by-Step Guide to Lithium Battery Pack Assembly and Cell Making Equipment

The rise of electric vehicles, renewable energy systems, and portable electronics has significantly increased the demand for lithium-ion batteries. But behind these powerful energy sources lies a highly intricate and controlled manufacturing process. From raw materials to finished products, battery-making machines and advanced battery-making equipment are essential in ensuring efficiency, precision, and safety at every […]

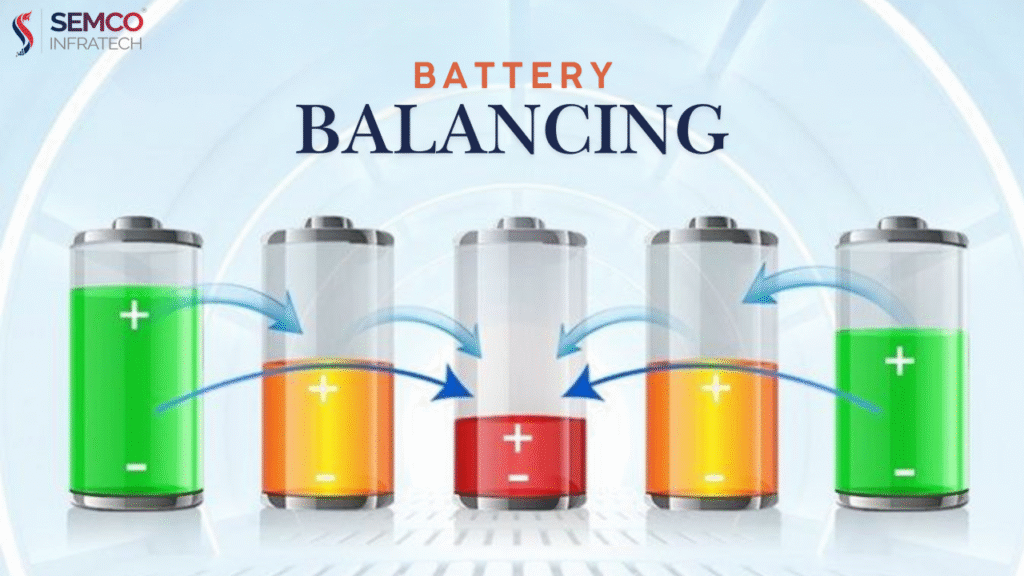

Battery Balancing: Key to Long-Lasting Lithium-Ion Packs

Ever notice your EV battery aging faster than expected or your laptop shutting down at 80% charge? The silent culprit is usually battery imbalance, and the unsung hero fixing it is the battery balancer within the Battery Management System (BMS). Balancing ensures every cell in your lithium-ion battery pack charges and discharges evenly, preventing overstrain […]

Enhancing EV Performance: Optimizing Battery Pack Integration with a Comprehensive Approach

Integrating a high-voltage battery pack into an electric vehicle (EV) is no small feat. The complexity arises from the pack’s substantial size, considerable weight, and the critical safety measures required during its operation. With the growing demand for lithium-ion batteries and advancements in battery-making machines, manufacturers must take a holistic approach to integration that balances […]

BMS Testers by Semco Infratech for Reliable Battery Pack Validation

In the dynamic world of lithium-ion battery assembly, the Battery Management System (BMS) plays a pivotal role in maintaining battery health, safety, and efficiency. Ensuring that every BMS functions flawlessly is essential for the success of any lithium battery pack assembly. To meet this crucial need, Semco Infratech, a trusted name in battery-making equipment, offers […]

How Welding Quality and Equipment Impact Lithium Battery Pack Assembly?

In the lithium-ion battery assembly process, precision is everything. One of the most critical stages is spot welding, which plays a fundamental role in the lithium battery pack assembly. This technique is used to securely join essential components such as nickel strips, battery cells, and protection plates, forming a durable and efficient battery pack. The […]

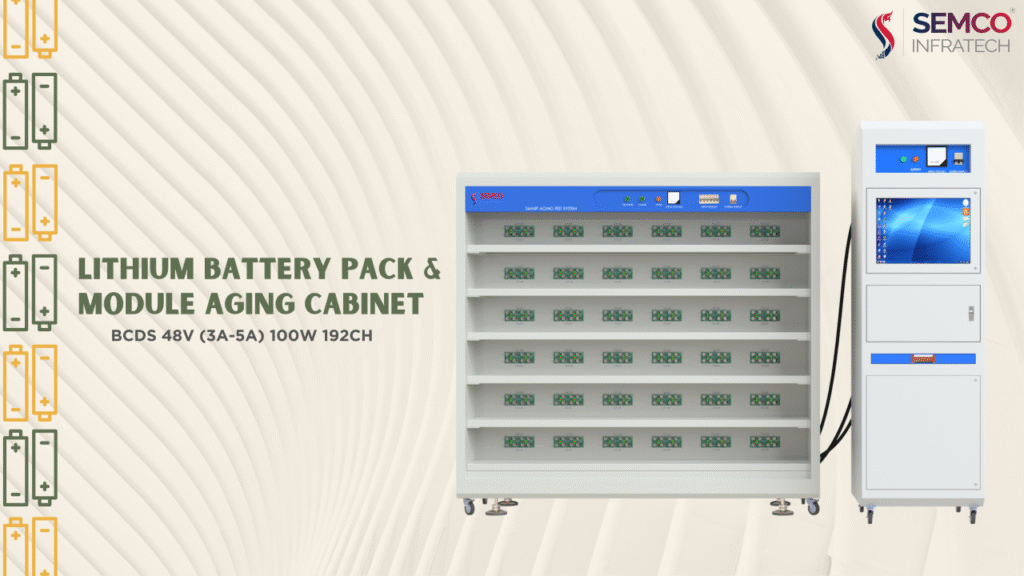

Lithium Battery Pack & Module Aging Cabinet: Semco SI-PT CT BCDS 48V (3A-5A) 100W 192CH

As the global transition to electric vehicles and renewable energy accelerates, the demand for reliable lithium-ion battery testing solutions has reached new heights. In response, Semco Infratech Pvt. Ltd., a pioneer in battery testing technologies, introduces a powerful solution: the Semco SI-PT CT BCDS 48V (3A-5A) 100W 192CH – a high-performance battery pack and module […]

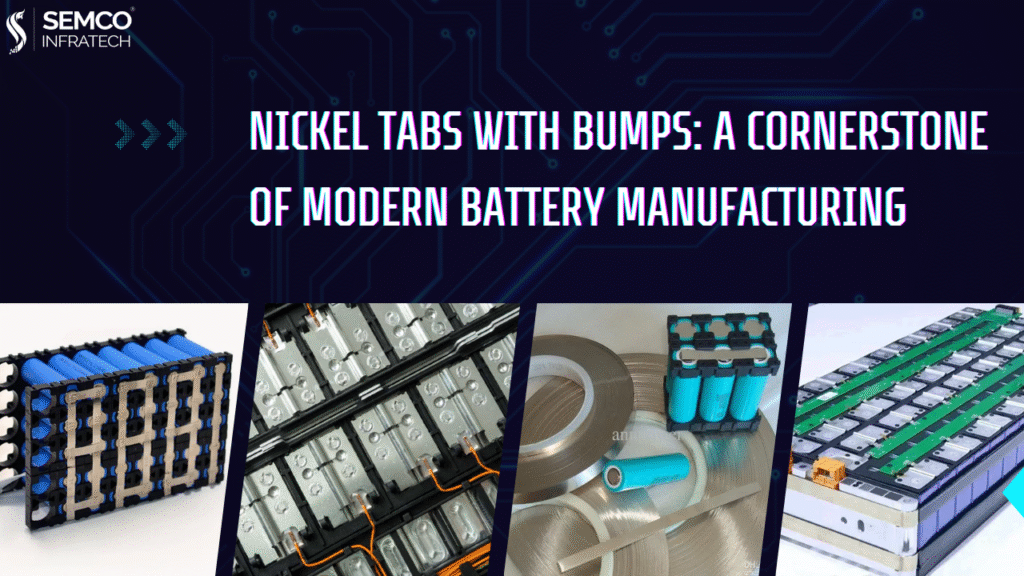

Nickel Tabs with Bumps: A Cornerstone of Modern Battery Manufacturing

In the ever-evolving field of battery manufacturing, where precision and performance are paramount, even the smallest components play a critical role. Nickel tabs with bumps, though seemingly simple, are indispensable to the functionality and efficiency of modern batteries. This article explores the significance, design, and applications of nickel tabs with bumps, highlighting their contribution to […]

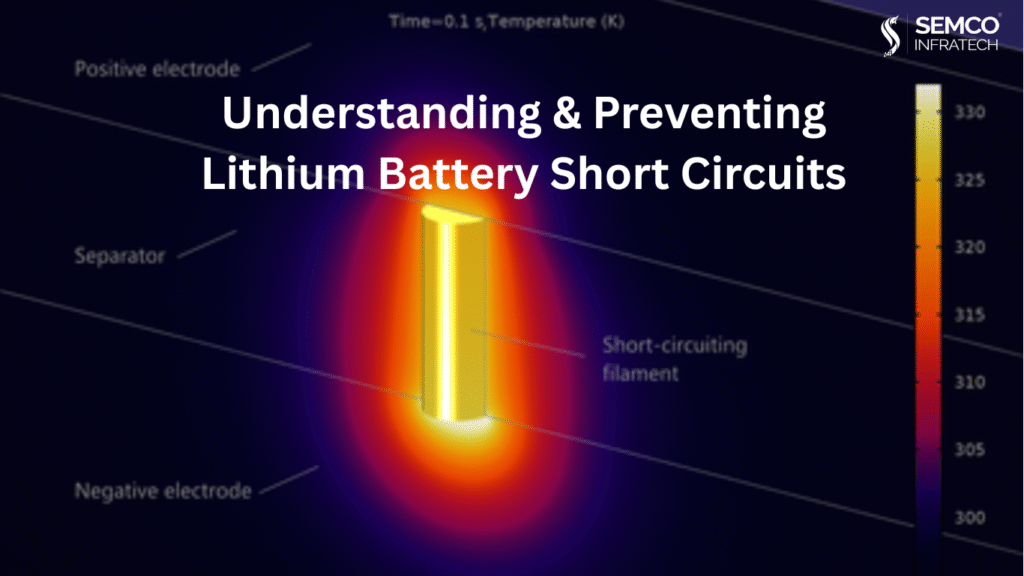

Preventing the Silent Threat: Understanding and Mitigating Short Circuits in Lithium Battery Manufacturing

The remarkable energy density and performance characteristics of lithium batteries have propelled them to the forefront of energy storage technology. However, inherent in their electrochemical nature is the potential for internal or external short circuits, an abnormal condition characterized by a sudden and drastic increase in current flow. These short circuits can lead to rapid […]

Addressing Negative Electrode Bulging During Lithium-Ion Battery Manufacturing

Lithium-ion batteries are vital for modern energy storage, but production challenges, like negative electrode bulging after the rolling process, hinder performance. This article analyses the causes of this bulging and proposes practical solutions to enhance battery consistency and reliability using advanced battery making machine, battery making equipment, and optimized lithium-ion battery assembly processes. Causes of […]

Battery Aging and Testing System for Modern Energy Storage Solutions

In the rapidly evolving field of battery technology, efficient and accurate battery aging and performance testing systems are essential for quality control and R&D. The 60V 20A 40-Channel Battery Charge-Discharge System (BCDS) represents a next-generation solution for comprehensive battery module testing and is ideal for testing pouch cell, li on pouch cell, and lithium pouch […]