In the dynamic world of lithium-ion battery assembly, the Battery Management System (BMS) plays a pivotal role in maintaining battery health, safety, and efficiency. Ensuring that every BMS functions flawlessly is essential for the success of any lithium battery pack assembly.

To meet this crucial need, Semco Infratech, a trusted name in battery-making equipment, offers a powerful lineup of BMS testers designed for precise, comprehensive validation of BMS protection boards.

Engineered for Accuracy in BMS Protection Board Testing

Semco’s BMS Cylindrical Battery Pack Testing Machines and BMS Prismatic Battery Pack Testing Machines are purpose-built to assess the safety and operational readiness of BMS units integrated into various battery systems. These solutions are essential for manufacturers involved in battery cell-making machine processes, ensuring each BMS can handle real-world stressors such as overvoltage, overcurrent, overheating, and short circuits.

Flexible Configurations: Testing from 1 to 52 Strings

Whether you’re working on a single-cell prototype or a complex multi-string battery pack, Semco provides versatile testers that support configurations from 1 to 52 strings. This broad scalability suits everything from portable devices to EVs and grid-level lithium-ion battery assembly process applications.

Integrated Smart Features for Modern Battery Packs

Equipped with advanced functionalities, Semco’s BMS testers offer:

- Temperature sensor supports for simulating various thermal conditions.

- CAN communication for direct interface with the BMS firmware.

- Real-time monitoring and diagnostics.

- Command-based communication for precise testing protocols.

These features make them ideal for validating sophisticated BMS units used in smart and connected battery systems.

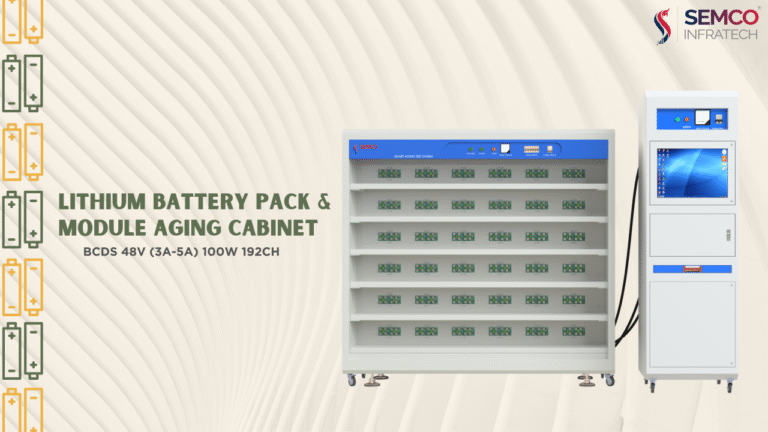

Multiple Formats: Desktop and Cabinet Models

Whether you are operating in an R&D environment or on a large-scale production floor, Semco’s testers are available in:

- Compact desktop units for prototyping and laboratory use.

- Full cabinet systems for industrial, high-throughput testing.

This range meets the needs of diverse users, from research institutions to full-scale battery-making machine factories.

Applications Across Industries

Semco’s BMS testers are widely used in:

- Electric vehicle BMS testing and development.

- Energy storage system validation.

- Battery pack QC in manufacturing.

- Repair and maintenance centres.

- R&D facilities focusing on lithium-ion innovation.

Why Choose Semco’s BMS Testing Solutions?

- Compatible with both cylindrical and prismatic battery packs.

- Accurate detection and reporting of protection parameters.

- Scalable options to fit all production scales.

- Supports BMS Cylindrical Battery Pack Tester and BMS Testers for Prismatic Cells.

- Seamless integration with smart BMS protocols.

- Backed by expert technical support from Semco.

Conclusion

In today’s competitive energy landscape, verifying the integrity of your BMS is a necessity, not a luxury. Semco Infratech’s battery-making machines and BMS testing equipment provide the precision, flexibility, and scalability you need to ensure safety and compliance. From the lab bench to the production floor, trust Semco’s advanced battery-making equipment to deliver uncompromising performance and reliability.