- Home

- Test

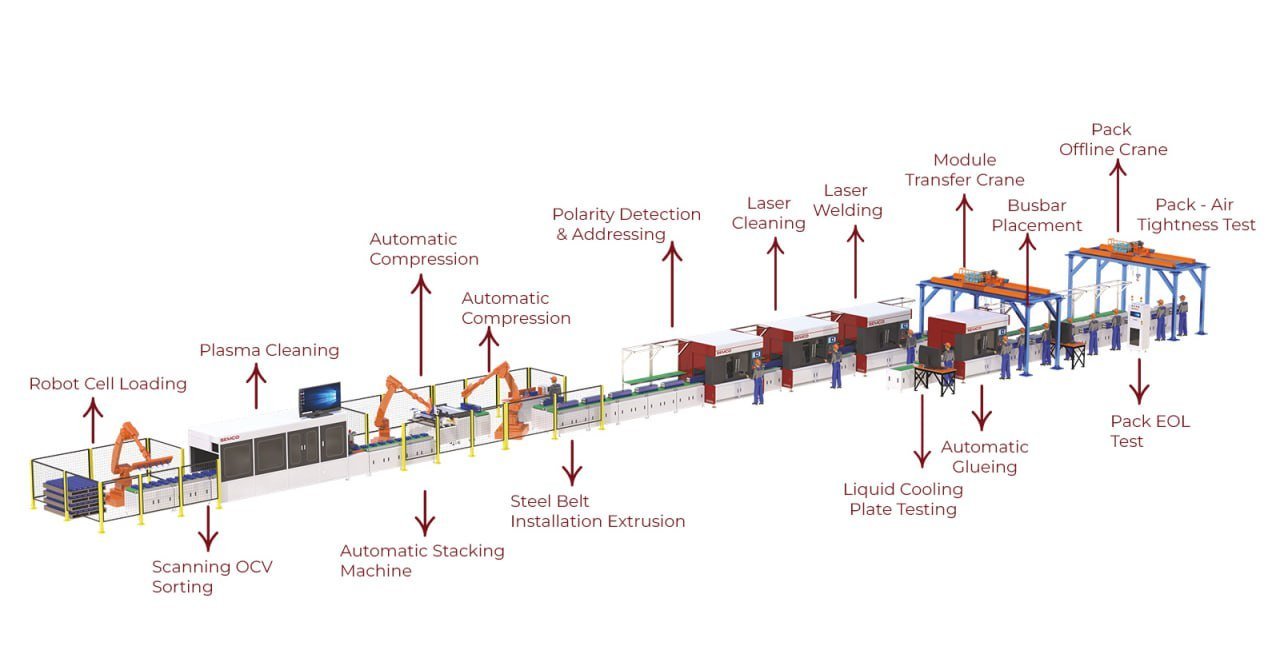

Prismatic Fully Automatic Assembly Line

Technical Excellence

Prismatic Fully Automatic Assembly Line

The Prismatic Fully Automatic Assembly Line is designed to deliver maximum throughput, consistency, and production reliability for modern energy storage applications. The line integrates cell aging, OCV sorting, automatic stacking, compression, laser cleaning, polarity inspection, laser welding, and comprehensive end-of-line (EOL) testing into a seamless automated workflow.

With real-time monitoring, precision vision systems, and fully automated material handling, the system minimizes human intervention while ensuring strict quality control at every stage. Its modular architecture allows easy scalability and adaptation to different prismatic cell formats, making it ideal for manufacturers targeting high-volume, high-yield battery pack production.

The Prismatic Fully Automatic Assembly Line is designed to deliver maximum throughput, consistency, and production reliability for modern energy storage applications. The line integrates cell aging, OCV sorting, automatic stacking, compression, laser cleaning, polarity inspection, laser welding, and comprehensive end-of-line (EOL) testing into a seamless automated workflow.

With real-time monitoring, precision vision systems, and fully automated material handling, the system minimizes human intervention while ensuring strict quality control at every stage. Its modular architecture allows easy scalability and adaptation to different prismatic cell formats, making it ideal for manufacturers targeting high-volume, high-yield battery pack production.

Key Fixture Features

- Covers the complete process from cell aging and sorting to module assembly, welding, and EOL testing without manual handling.

- Integrated OCV sorting, polarity detection, CCD vision inspection, IR testing, and withstand voltage testing ensure consistent product quality.

- Optimized for mass production with automatic stacking, compression, and laser welding to support large ESS battery volumes.

- High-power laser welding combined with vision cameras delivers accurate, repeatable weld quality and traceability.

- Modular structure allows easy expansion, format changeover, and integration into existing factory MES and pack lines.

Test

- OCV Tester

- Automatic Stacking Machine

- Extrusion Machine

- Polarity Detection

- Laser Cleaning

- Laser Welding

- Module EOL Tester

- Pack EOL Test

OCV Tester

Measures the open-circuit voltage of incoming cells. Ensures quality screening before automation.

Automatic Stacking Machine

Stacks cells with robotic precision. Enables high-speed, high-accuracy production.

Extrusion Machine

Applies controlled compression to stabilize modules. Improves thermal and structural performance.

Polarity Detection

Confirms correct cell orientation automatically. Prevents polarity-related failures.

Laser Cleaning

Cleans welding surfaces for defect-free joints. Ensures optimal electrical conductivity.

Laser Welding

Performs fast, precise, and repeatable welds. Ideal for large-scale prismatic battery production.

Module EOL Tester

Validates module safety and performance. Ensures compliance with global standards.

Pack EOL Test

Final inspection of battery pack functionality and safety. Certifies the pack for deployment and shipment.

Request a Quote

- Patparganj Industrial Area, New Delhi

- sales@semcoindia.com

- +91-9289038327

Overview

Suitable for industries such as:

EV battery production, energy storage manufacturing, battery research labs, electronics assembly, and OEM-based fabrication units.

Product Specifications

This equipment is designed to support efficient and accurate battery assembly and testing workflows. With durable construction, precision control, and user-friendly operation, it delivers consistent performance for both small-scale and large-scale production environments.

Prismatic Fully Automatic Assembly Line

Product Name

Description

Cell Aging Machine

- 5V 60A 8CH

- 5V 60A 64CH

Battery Pack Tester

- 60V 60A – 2CH/4CH/6CH/12CH

- 60V 100A- 2CH/4CH/6CH/8CH

- 100V 100A- 1CH/2CH/4CH/6CH/8CH

OCV Sorting

- HIOKI BT3561A (4Channel +1NG)

Module Stacking

- Automatic

Compression

- Automatic Adjustable pressure (10-1500 Kgf)

Laser Cleaning

- 200W

Ploarity & CCD Tester

- Hikvision 12MP

Laser Welding

- 1200W/200W/3000W/6000W

- Open/Closed Cabinet

- With Vision Camera

Module EOL

- IR Tester & withstand voltage tester

Module Transfer Crane

Pack Line

- Air Tightness Test

- Leak Test

Applications

- Lithium-ion battery assembly and production units

- EV battery manufacturing facilities

- QC and testing labs

- R&D facilities

- OEM and contract manufacturing plants

Support & Warranty

The product comes with a dedicated support and service package that includes activation, calibration assistance, and post-installation guidance.

- Standard warranty period

- Spare part availability details

- On-site / online installation support

- AMC (Annual Maintenance Contract) option

- Technical support contact email

Faq

Frequently Asked Questions

Find quick answers to common questions about our BESS Assembly Line, including automation capabilities, supported battery types, customization options, safety standards, and production scalability.