As the demand for electric vehicles (EVs), energy storage systems, and portable devices continues to grow, lithium-ion battery assembly has become a cornerstone of next-generation energy infrastructure. However, beyond cell chemistry and pack design, a crucial process often goes unnoticed — air leak testing.

At Semco Infratech, we emphasize that leak-free battery packs aren’t a luxury — they’re a standard for safety, performance, and brand integrity. Our Semco Air Leak Tester ensures each battery pack meets the highest quality benchmarks.

Why Air Leakage Testing Is Essential?

Air leakage testing is a non-destructive procedure that validates the enclosure integrity of battery packs. It ensures external contaminants like air or moisture cannot penetrate the system, and internal gases don’t escape.

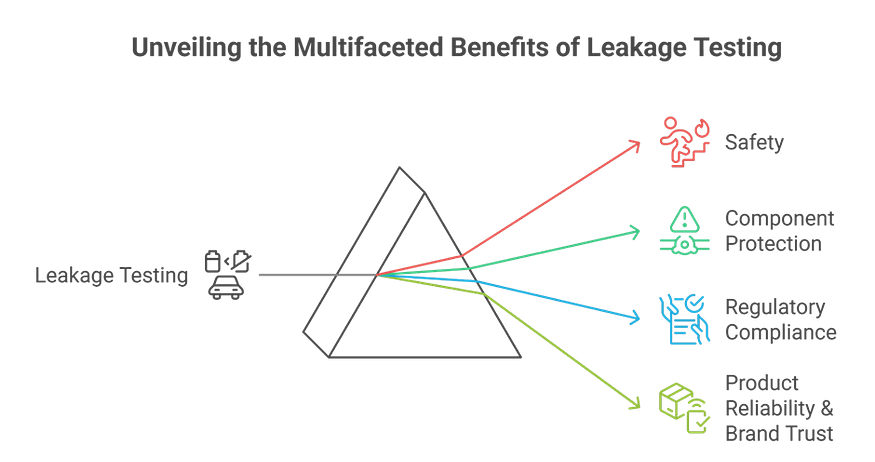

Key Benefits:

- Safety First: Prevents moisture ingress that could trigger short circuits or thermal runaway, especially critical in EVs.

- Component Protection: Shields battery cell making machine components, and the BMS from humidity-induced degradation.

- Regulatory Compliance: Helps meet standards like UN 38.3 and ISO, essential for lithium-ion battery assembly.

- Reliability & Brand Trust: Fewer failures mean fewer warranty claims and stronger customer confidence.

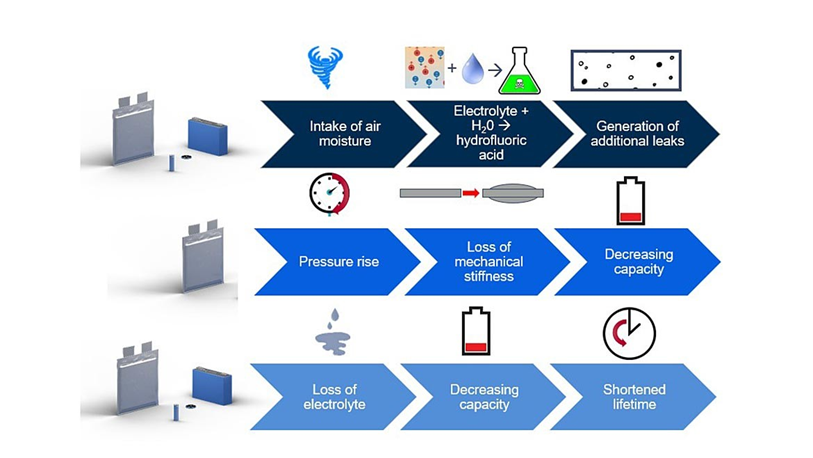

Risks of Skipping Leak Testing

Failing to implement air leak testing in your battery-making machine workflow can result in:

- Battery swelling or bulging.

- Moisture-related short circuits and fires.

- Shorter battery lifespan due to corrosion.

- Costly product recalls or reputational damage.

How Semco Air Leak Testers Work?

Our testers operate using compressed air to evaluate the seal integrity of battery packs. Advanced pressure sensors identify even the tiniest drops in pressure.

Features:

- Configurable pressure range (30 kPa to 500 kPa)

- Digital curve monitoring on a 7″ display

- Barcode scanning for traceability

- Auto screenshot and data storage

- Cloud monitoring for smart factory integration

Why Choose Semco?

Semco Infratech provides industry-leading battery-making equipment like the Semco Air Leak Tester, tailored for both production lines and field servicing.

Advantages:

- High-sensitivity sensors (±3 Pa accuracy)

- Real-time visualization

- Rugged and compact industrial design

- User-friendly touchscreen interface

- Compatible with all lithium battery pack assembly lines

Conclusion

In the lithium-ion battery assembly process, air leakage testing is a mission-critical step. With Semco’s advanced solutions, manufacturers can produce safe, compliant, and long-lasting battery packs.

Semco Air Leak Tester is the trusted choice for top manufacturers aiming for zero-defect battery-making equipment and leak-proof battery cell-making machines.