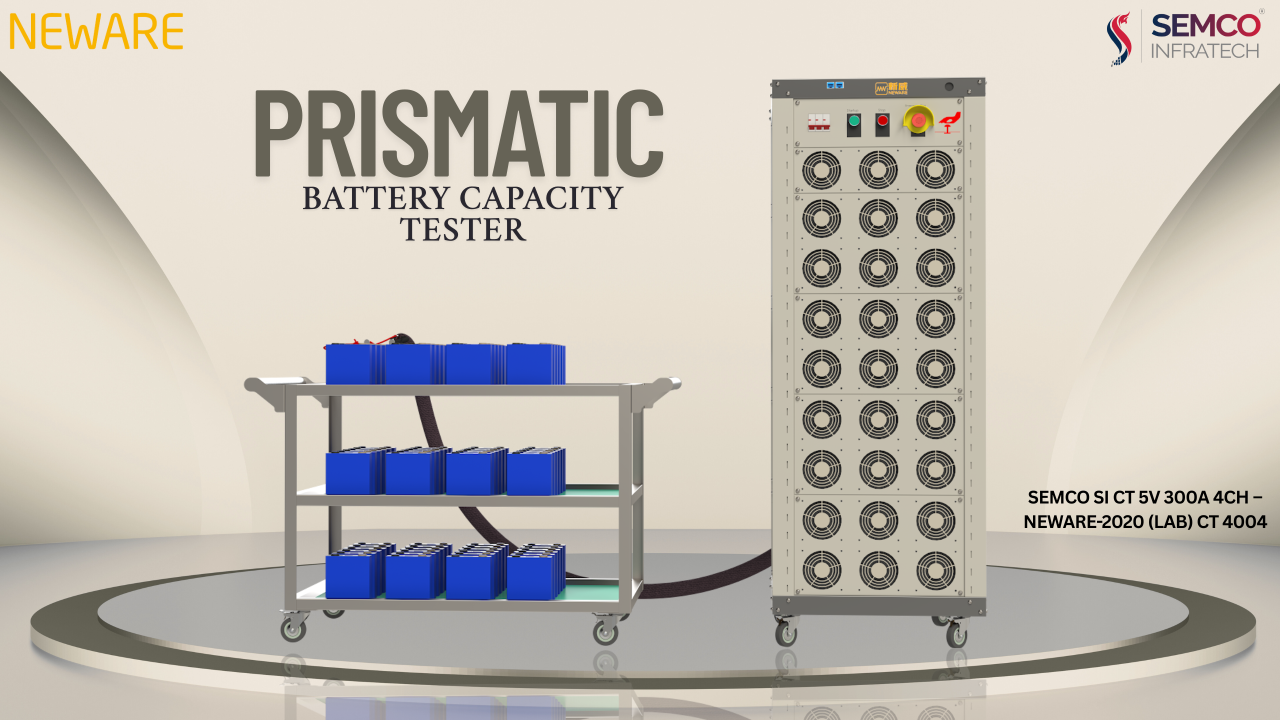

The Semco SI CT 5V 300A 4CH — Neware-2020 (LAB) CT 4004 is an advanced battery testing solution engineered for modern lithium-ion battery assembly labs and R&D centres.

Ideal for both academic institutions and industrial facilities, this high-performance equipment ensures precision, flexibility, and robust functionality required for cutting-edge battery cell-making machine environments.

High-Precision Electrical Performance

This four-channel battery testing system delivers power via a 380V AC input and a total output of 6000W. Each of its four independent channels features:

- Voltage Range: 0.025V to 5V with ±0.1% FS accuracy

- Current Range: 1.5A to 300A with ±0.1% FS accuracy

- Output Per Channel: 1500W

- Stable CV and CC modes

This makes it perfect for validating cells used in any lithium-ion battery assembly process.

Flexible Charging & Discharging Modes

The CT 4004 offers versatile testing for various battery-making equipment applications:

- Charging: CC, CV, CCCV, Constant Power

- Discharging: CC, CP, Constant Resistance

- Pulse Testing: Up to 32 cycles, 500ms minimum pulse width

- DCIR Testing: Direct Current Internal Resistance

Data Management & Protection

Featuring 16-bit AD/DA resolution and a minimum data record interval of 100ms, it ensures accurate monitoring.

- Voltage Change Detection: 10 mV

- Current Change Detection: 600mA

- Data Export: XLS, PDF, TXT

- Supports MySQL Databases

Its robust software and hardware protections are vital for safe lithium battery pack assembly testing.

Programmable Cycles and Steps

Support for up to 65,535 cycles and 254 steps with 3-level nested loops makes it adaptable for complex battery-making machine test scenarios. Independent channel control and Kelvin connections ensure accuracy.

Auxiliary Channel Integration

- Up to 248 temperature and voltage auxiliary inputs

- Temp Range: -25°C to 110°C (±1°C)

- Voltage: -5V to 5V (±0.1%)

- Configurable ΔV triggers and safety settings

(Not compatible with soft-reset battery protection boards.)

User-Friendly & Lab-Ready

With Ethernet communication, Windows 7/10 support, and a 30U rack form (600×600×1520 mm), it’s easy to install in professional battery cell making machine labs.

- Noise: <85 dB

- Storage: 500GB HDD required

- IP20-rated housing

Environmental Compatibility

- Operating Temp: 0°C to 40°C

- Storage Temp: -10°C to 50°C

- Humidity Tolerance: Up to 70% operational, 80% storage (no condensation)

Conclusion

The Semco SI CT 4004 is a powerful, lab-grade battery testing platform engineered to support the growing demands of lithium-ion battery assembly, battery-making machines, and lithium battery pack assembly validation.