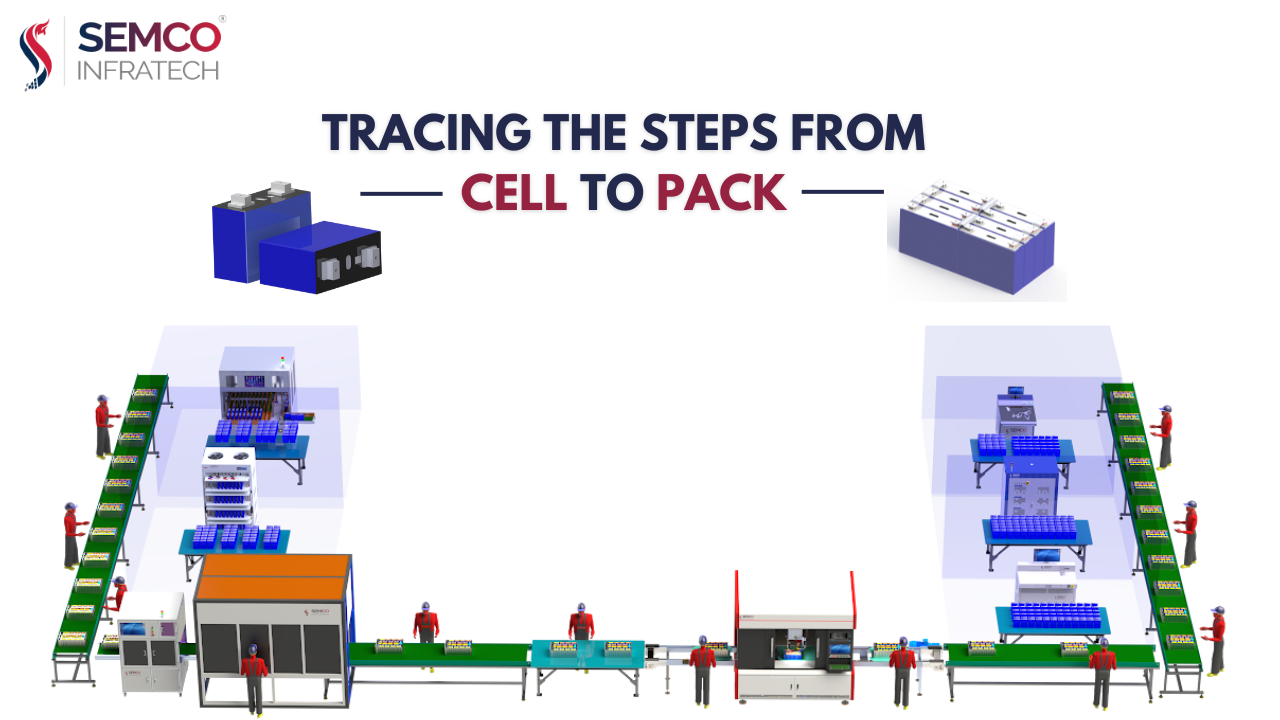

As the demand for electric vehicles (EVs) and energy storage solutions surges, the efficiency of lithium-ion battery assembly lines plays a crucial role in determining the success of battery manufacturers. A well-optimized assembly line ensures high precision, consistency, and cost-effectiveness. But how does the process work? Let’s dive into the key stages of a lithium-ion battery assembly line.

Cell Grading: The Foundation of Excellence

Cell grading is a crucial first step in the process when each battery cell is carefully examined to ascertain its performance parameters. To produce a thorough “report card” for every cell, capacity, and internal resistance are carefully examined. This methodical procedure guarantees uniformity and groups cells according to their performance attributes, establishing the groundwork for the best possible utilization of a battery pack.

Cell Sorting: Precision in Pairing

After grading, cells are sorted based on their specifications, optimizing the performance of the final battery pack. By ensuring that the batteries in a pack are precisely matched, this precision matching maximizes performance and prolongs battery life. To fully utilize each cell’s potential within the battery pack’s overall power, this phase must be carefully planned.

OCV Testing Machines

Open Circuit Voltage (OCV) testing machines measure the voltage of cells to ensure they meet the required standards before assembly.

CCD Polarity Tester

This equipment is used for precise alignment and assembly of battery components, enhancing the overall efficiency of the production process.

BMS Testing: The Guardian of Performance

At the heart of the battery pack lies the Battery Management System (BMS), serving as its vigilant guardian. Before integration, the BMS undergoes rigorous testing to validate its functionality and its ability to effectively communicate with the individual cells. This crucial step ensures that the BMS is equipped to monitor and regulate the health and performance of the battery pack with unwavering precision.

Cell Welding: Where Precision Meets Connectivity

As the testing cells await their transformation into a unified force, the delicate process of cell welding takes center stage. Automated robotic arms execute this task with precision, forging strong and reliable electrical connections between the cells. The seamless integration achieved through cell welding forms the foundational framework for the battery pack, ensuring its resilience and efficiency.

Battery Pack Testing or Aging: Trials of Endurance

The culmination of the assembly line journey leads to the final stage – rigorous testing of the complete battery pack. Depending on its intended application, this phase may encompass charging/discharging cycles to simulate real-world usage or accelerated aging tests to evaluate long-term performance and safety. Through these trials of endurance, the battery pack’s resilience and reliability are put to the test, ensuring its readiness for the demands of modern life.

Battery Comprehensive Testing

Finally, comprehensive testing machines assess the battery packs’ overall functionality, safety, and longevity before they are ready for deployment. The integration of these advanced machines not only streamlines the production process but also ensures that you deliver high-quality, reliable battery packs that power the future of transportation.

Conclusion: Precision, Innovation, and Reliability

From the meticulous grading of individual cells to the comprehensive testing of the assembled battery pack, the cell-to-battery assembly line embodies a fusion of precision, innovation, and reliability. Each step in this intricate process plays a pivotal role in shaping the quality, safety, and performance of the batteries that power our modern world. Behind every seamless charge and every enduring power source lies a journey of expertise and dedication, culminating in the creation of batteries that stand as pillars of energy in our technologically driven lives.