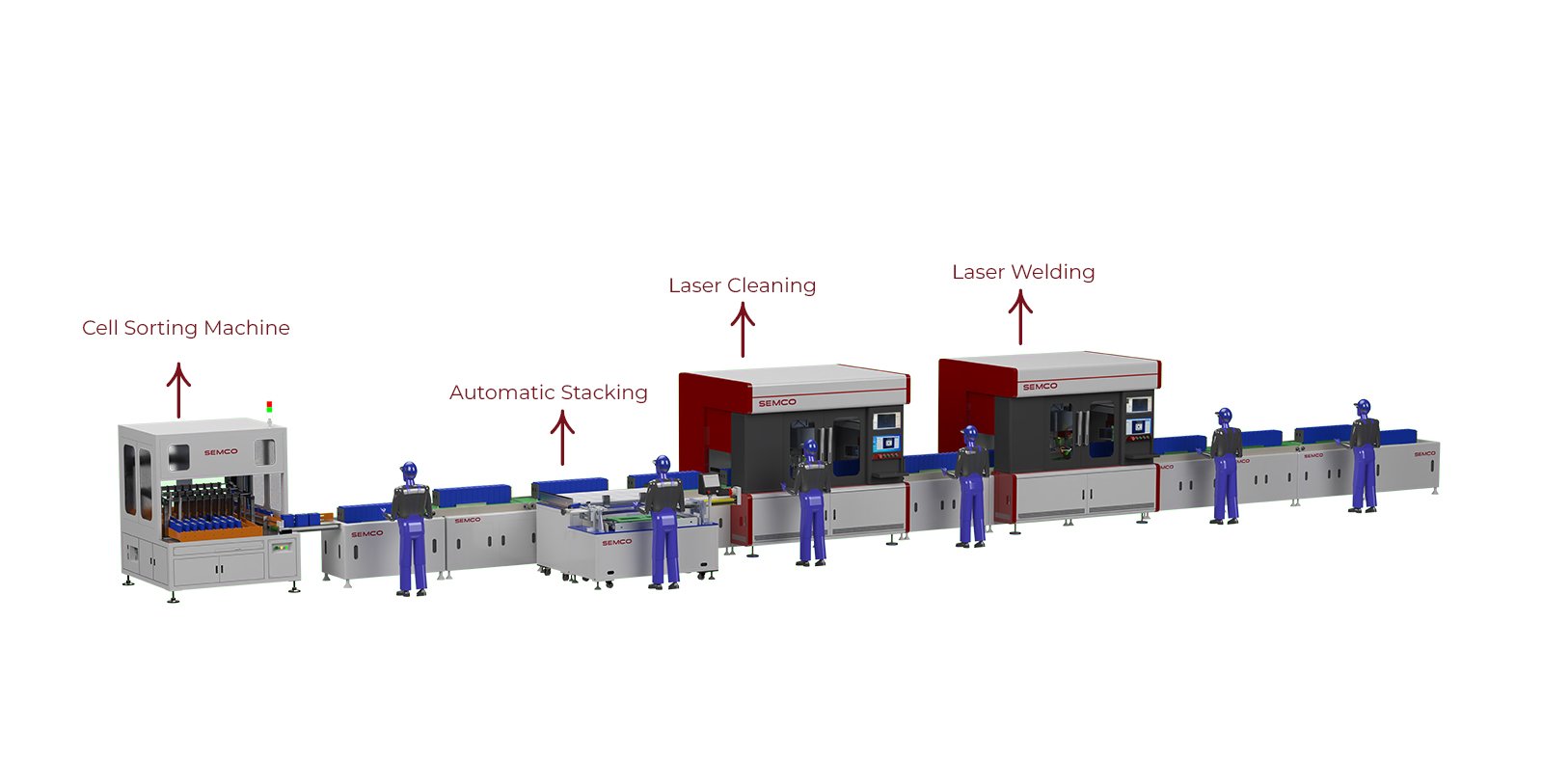

The Prismatic Semi-Automatic – 2 Terminal Assembly Line is designed to deliver an optimal balance between advanced automation and investment efficiency for lithium battery manufacturers. Built around dual-terminal processing, the line integrates precision laser welding, laser cleaning, CCD inspection, extrusion assembly, and comprehensive testing within a compact, semi-automated layout.

By combining in-line automated stations with strategically positioned offline processes, this system achieves higher productivity and improved process stability while maintaining a manageable footprint. Its modular architecture supports seamless expansion from pilot lines to mid-volume manufacturing, making it an ideal solution for producers seeking to scale operations without transitioning to full automation.

Selects and groups cells for dual-terminal battery designs. Improves pack symmetry and performance.

Accurately stacks cells for dual-terminal assembly. Reduces manual handling and alignment errors.

Prepares terminal surfaces for high-quality welding. Enhances weld strength and reliability.

Forms secure dual-terminal electrical connections. Supports higher current and improved durability.

EV battery production, energy storage manufacturing, battery research labs, electronics assembly, and OEM-based fabrication units.

This equipment is designed to support efficient and accurate battery assembly and testing workflows. With durable construction, precision control, and user-friendly operation, it delivers consistent performance for both small-scale and large-scale production environments.

Product Name

Description

Cell Grading Machine

Battery Sorting Machine

Battery Stacking Pressing Machine

Laser Cleaning Machine

Laser Welding Machine

BMS Tester

Battery Pack Comprehensive Tester

Battery Aging Machine

The product comes with a dedicated support and service package that includes activation, calibration assistance, and post-installation guidance.

Find quick answers to common questions about our BESS Assembly Line, including automation capabilities, supported battery types, customization options, safety standards, and production scalability.